| IEA EBC Annex 60 |

|

Package with base classes that facilitate exporting models as an FMU

This package contains blocks that serve as containers for exporting

models from Annex60.Fluid as a Functional Mockup Unit (FMU).

This allows using models from Annex60.Fluid, add them

to a block that only has input and output signals, but no acausal connectors,

and then export the model as a Functional Mockup Unit.

Models can be individual models or systems that are composed of various

models.

For more information, see the

User's Guide.

Extends from Modelica.Icons.Package (Icon for standard packages).

| Name | Description |

|---|---|

| User's Guide | |

| Model of a flow splitter that can be exported as an FMU | |

| Model of a sink with temperature for reverse flow as an input that can be exported as an FMU | |

| Model of a boundary with mass flow rate, pressure and temperature as an input that can be exported as an FMU | |

| Package with adaptors to connect models with fluid ports and models with signal ports | |

| Package with blocks that convert between different connectors | |

| Package with containers to export thermofluid flow models | |

| Collection of validation models | |

| Package with interfaces for models that serves as an FMU container | |

| Package with base classes for Annex60.Fluid.FMI |

Annex60.Fluid.FMI.FlowSplitter_u

Annex60.Fluid.FMI.FlowSplitter_u

Model of a flow splitter that can be exported as an FMU

Block that takes as an input the inflowing fluid at the port inlet

and a vector of control signals for the mass flow rates u.

The mass flow of all outlet ports i

is set to the value of u[i] m_flow_nominal[i].

If the inflowing mass flow rate at the port inlet is not equal

to the sum of u[i] m_flow_in[i], the simulation stops with an assert.

The mass flow rates at all outlet ports must be non-negative. Reverse flow is not yet implemented. If either of these limitations are violated, then the model stops with an error.

Extends from Modelica.Blocks.Icons.Block (Basic graphical layout of input/output block).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | Modelica.Media.Interfaces.Pa... | Medium in the component | |

| MassFlowRate | m_flow_nominal[nout] | Nominal mass flow rate for each outlet [kg/s] | |

| Integer | nout | Number of outlets | |

| Boolean | use_p_in | true | = true to use a pressure from connector, false to output Medium.p_default |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = true to allow flow reversal, false restricts to design direction (inlet -> outlet) |

| Type | Name | Description |

|---|---|---|

| replaceable package Medium | Medium in the component | |

| Inlet | inlet | Fluid inlet |

| Outlet | outlet[nout] | Fluid outlet |

| input RealInput | u[nout] | Control signal for the mass flow rates [1] |

Annex60.Fluid.FMI.Sink_T

Annex60.Fluid.FMI.Sink_T

Model of a sink with temperature for reverse flow as an input that can be exported as an FMU

Model of a sink that takes as an input the medium properties

temperature, mass fractions (if Medium.nXi > 0)

and trace substances (if Medium.nC > 0).

These properties are used during reverse flow.

For a system of components with the connectors of the Annex60.Fluid.FMI package, this component is required to set the medium properties for the reverse flow.

If the parameter use_p_in is set to true,

then the model has an output connector p.

This can be used to obtain the pressure of the sink, which

may be needed to iteratively solve for the mass flow rate.

Extends from Modelica.Blocks.Icons.Block (Basic graphical layout of input/output block).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | Modelica.Media.Interfaces.Pa... | Medium in the component | |

| Boolean | use_p_in | true | = true to use a pressure from connector, false to output Medium.p_default |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = true to allow flow reversal, false restricts to design direction (inlet -> outlet) |

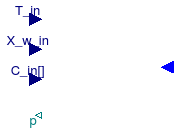

| Type | Name | Description |

|---|---|---|

| replaceable package Medium | Medium in the component | |

| input RealInput | T_in | Prescribed boundary temperature [K] |

| input RealInput | X_w_in | Prescribed boundary composition [1] |

| input RealInput | C_in[Medium.nC] | Prescribed boundary composition |

| Inlet | inlet | Fluid port |

| output PressureOutput | p | Pressure [Pa] |

Annex60.Fluid.FMI.Source_T

Annex60.Fluid.FMI.Source_T

Model of a boundary with mass flow rate, pressure and temperature as an input that can be exported as an FMU

Model of a source that takes as an input the mass flow rate,

pressure and the medium properties

temperature, mass fractions (if Medium.nXi > 0)

and trace substances (if Medium.nC > 0).

For a system of components with the connectors of the Annex60.Fluid.FMI package, this component is required to set the pressure and the mass flow rate of the system.

Extends from Modelica.Blocks.Icons.Block (Basic graphical layout of input/output block).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | Modelica.Media.Interfaces.Pa... | Medium in the component | |

| Boolean | use_p_in | true | = true to use a pressure from connector, false to output Medium.p_default |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = true to allow flow reversal, false restricts to design direction (inlet -> outlet) |

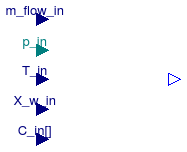

| Type | Name | Description |

|---|---|---|

| replaceable package Medium | Medium in the component | |

| input RealInput | m_flow_in | Prescribed mass flow source [kg/s] |

| input PressureInput | p_in | Prescribed boundary pressure [Pa] |

| input RealInput | T_in | Prescribed boundary temperature [K] |

| input RealInput | X_w_in | Prescribed boundary composition [1] |

| input RealInput | C_in[Medium.nC] | Prescribed boundary composition |

| Outlet | outlet | Fluid port |