Collection of validation models

Information

This package contains validation models for the classes in

Annex60.Fluid.FMI.

Note that most validation models contain simple input data

which may not be realistic, but for which the correct

output can be obtained through an analytic solution.

The examples plot various outputs, which have been verified against these

solutions. These model outputs are stored as reference data and

used for continuous validation whenever models in the library change.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

Package Content

| Name |

Description |

FlowSplitter_u FlowSplitter_u

|

Flow splitter |

HeaterFan HeaterFan

|

Heater and fan in series, model configured to allow flow reversal |

HeaterFanPressureDriven HeaterFanPressureDriven

|

Heater and fan in series, model configured to allow flow reversal and pressure driven flow rate |

HeaterFan_noReverseFlow HeaterFan_noReverseFlow

|

Heater and fan in series, model configured to not allow flow reversal |

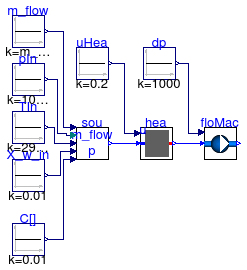

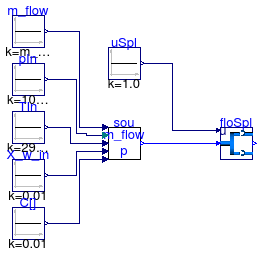

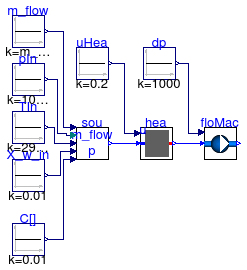

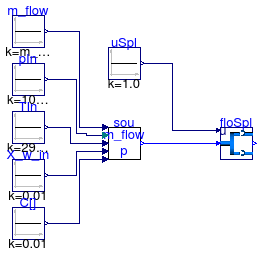

Flow splitter

Information

This example demonstrates how to configure a model with a flow splitter.

For this example, the model is not exported as an FMU. However, the

thermofluid flow models are wrapped using input/output blocks.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | 0.1 | Nominal mass flow rate [kg/s] |

| Boolean | use_p_in | false | = true to use a pressure from connector, false to output Medium.p_default |

| Assumptions |

| Boolean | allowFlowReversal | false | = true to allow flow reversal, false restricts to design direction (inlet -> outlet) |

Modelica definition

model FlowSplitter_u

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=0.1

;

parameter Boolean use_p_in = false

;

parameter Boolean allowFlowReversal = false

;

Modelica.Blocks.Sources.Constant uSpl(k=1.0) ;

Source_T sou(

redeclare package Medium = Medium,

use_p_in=use_p_in,

allowFlowReversal = allowFlowReversal)

;

Modelica.Blocks.Sources.Constant m_flow(k=m_flow_nominal*3) ;

Modelica.Blocks.Sources.Constant pIn(k=100000) ;

Modelica.Blocks.Sources.Constant TIn(k=293.15) ;

Modelica.Blocks.Sources.Constant X_w_in(k=0.01) ;

Modelica.Blocks.Sources.Constant C[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

ExportContainers.Examples.FMUs.FlowSplitter_u floSpl(

redeclare package Medium = Medium,

use_p_in=use_p_in,

allowFlowReversal=allowFlowReversal);

equation

connect(m_flow.y, sou.m_flow_in);

connect(sou.p_in, pIn.y);

connect(TIn.y, sou.T_in);

connect(C.y, sou.C_in);

connect(X_w_in.y, sou.X_w_in);

connect(floSpl.inlet, sou.outlet);

connect(floSpl.u[1], uSpl.y);

connect(floSpl.u[2], uSpl.y);

end FlowSplitter_u;

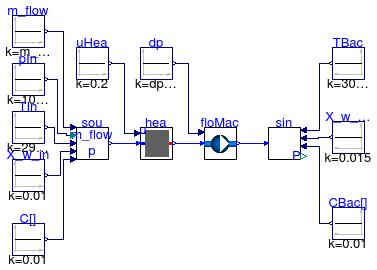

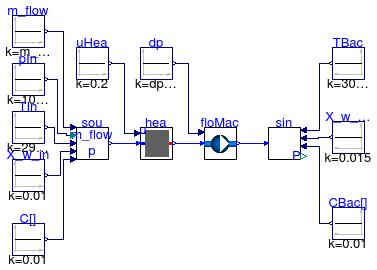

Heater and fan in series, model configured to allow flow reversal

Information

This example demonstrates how to configure a model with a heater

and a fan that causes a pressure rise in the air stream.

Note that the mass flow rate and the absolute pressure are

set by the component sou.

Therefore, the fan simply increases the pressure of the medium,

and it also computes how much power is needed for this pressure rise,

which is an input to the fan model.

For a model with that computes the mass flow rate based on the pressure drop, see

Annex60.Fluid.FMI.Validation.HeaterFanPressureDriven.

For this example, the models are not exported as FMUs. However, the

thermofluid flow models are wrapped using input/output blocks.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | Q_flow_nominal/1000/10 | Nominal mass flow rate [kg/s] |

| PressureDifference | dp_nominal | 2000 | Pressure [Pa] |

| HeatFlowRate | Q_flow_nominal | 1000 | Heat flow rate at u=1, positive for heating [W] |

| Boolean | use_p_in | true | = true to use a pressure from connector, false to output Medium.p_default |

Modelica definition

model HeaterFan

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=Q_flow_nominal/1000/10

;

parameter Modelica.SIunits.PressureDifference dp_nominal(displayUnit="Pa")=2000

;

parameter Modelica.SIunits.HeatFlowRate Q_flow_nominal = 1000

;

parameter Boolean use_p_in = true

;

ExportContainers.Examples.FMUs.Fan floMac(

redeclare final package Medium = Medium,

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

use_p_in=use_p_in) ;

ExportContainers.Examples.FMUs.HeaterCooler_u hea(

redeclare final package Medium = Medium,

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

Q_flow_nominal=Q_flow_nominal,

use_p_in=use_p_in) ;

Modelica.Blocks.Sources.Constant dp(k=dp_nominal) ;

Modelica.Blocks.Sources.Constant uHea(k=0.2) ;

Source_T sou(

redeclare package Medium = Medium, use_p_in=use_p_in)

;

Sink_T sin(

redeclare package Medium = Medium, use_p_in=use_p_in)

;

Modelica.Blocks.Sources.Constant m_flow(k=m_flow_nominal) ;

Modelica.Blocks.Sources.Constant pIn(k=100000) ;

Modelica.Blocks.Sources.Constant TIn(k=293.15) ;

Modelica.Blocks.Sources.Constant X_w_in(k=0.01) ;

Modelica.Blocks.Sources.Constant TBac(k=303.15)

;

Modelica.Blocks.Sources.Constant X_w_bac(k=0.015)

;

Modelica.Blocks.Sources.Constant CBac[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

Modelica.Blocks.Sources.Constant C[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

equation

connect(uHea.y, hea.u);

connect(dp.y, floMac.dp_in);

connect(sou.outlet, hea.inlet);

connect(hea.outlet, floMac.inlet);

connect(sin.inlet, floMac.outlet);

connect(sin.T_in, TBac.y);

connect(CBac.y, sin.C_in);

connect(m_flow.y, sou.m_flow_in);

connect(sou.p_in, pIn.y);

connect(TIn.y, sou.T_in);

connect(C.y, sou.C_in);

connect(X_w_in.y, sou.X_w_in);

connect(sin.X_w_in, X_w_bac.y);

end HeaterFan;

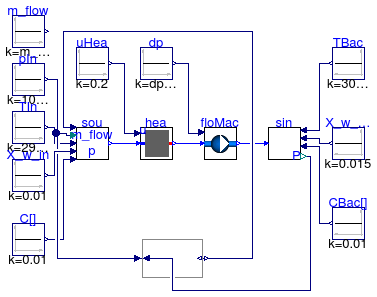

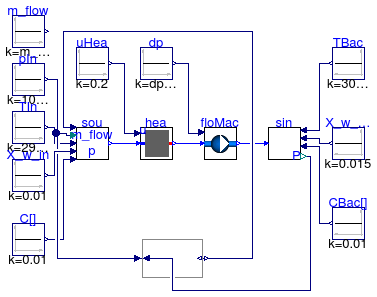

Heater and fan in series, model configured to allow flow reversal and pressure driven flow rate

Information

This example demonstrates how to configure a model with a heater

and a fan that causes a pressure rise in the air stream.

The fan increases the pressure of the medium,

and it also computes how much power is needed for this pressure rise,

which is an input to the fan model.

The component invBloCon at the bottom of the model sets up

an equality constraint on the pressure between the sink and the source.

It also outputs a signal for the mass flow rate. Hence, this component is

used to declare how to break the algebraic loop in this signal flow diagram.

For a model with prescribed mass flow rate, see

Annex60.Fluid.FMI.Validation.HeaterFan.

For this example, the models are not exported as FMUs. However, the

thermofluid flow models are wrapped using input/output blocks.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | Q_flow_nominal/1000/10 | Nominal mass flow rate [kg/s] |

| PressureDifference | dp_nominal | 2000 | Pressure [Pa] |

| HeatFlowRate | Q_flow_nominal | 1000 | Heat flow rate at u=1, positive for heating [W] |

Modelica definition

model HeaterFanPressureDriven

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=Q_flow_nominal/1000/10

;

parameter Modelica.SIunits.PressureDifference dp_nominal(displayUnit="Pa")=2000

;

parameter Modelica.SIunits.HeatFlowRate Q_flow_nominal = 1000

;

constant Boolean use_p_in = true

;

ExportContainers.Examples.FMUs.Fan floMac(

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

use_p_in=use_p_in) ;

ExportContainers.Examples.FMUs.HeaterCooler_u hea(

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

Q_flow_nominal=Q_flow_nominal,

use_p_in=use_p_in) ;

Modelica.Blocks.Sources.Constant dp(k=dp_nominal) ;

Modelica.Blocks.Sources.Constant uHea(k=0.2) ;

Source_T sou(

redeclare package Medium = Medium, use_p_in=use_p_in)

;

Sink_T sin(

redeclare package Medium = Medium, use_p_in=use_p_in)

;

Modelica.Blocks.Sources.Constant m_flow(k=m_flow_nominal) ;

Modelica.Blocks.Sources.Constant pIn(k=100000) ;

Modelica.Blocks.Sources.Constant TIn(k=293.15) ;

Modelica.Blocks.Sources.Constant X_w_in(k=0.01) ;

Modelica.Blocks.Sources.Constant TBac(k=303.15)

;

Modelica.Blocks.Sources.Constant X_w_bac(k=0.015)

;

Modelica.Blocks.Sources.Constant CBac[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

Modelica.Blocks.Sources.Constant C[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

Modelica.Blocks.Math.InverseBlockConstraints invBloCon

;

equation

connect(uHea.y, hea.u);

connect(dp.y, floMac.dp_in);

connect(sou.outlet, hea.inlet);

connect(hea.outlet, floMac.inlet);

connect(sin.inlet, floMac.outlet);

connect(sin.T_in, TBac.y);

connect(CBac.y, sin.C_in);

connect(sou.p_in, pIn.y);

connect(TIn.y, sou.T_in);

connect(C.y, sou.C_in);

connect(pIn.y, invBloCon.u1);

connect(sin.p, invBloCon.u2);

connect(invBloCon.y1, sou.m_flow_in);

connect(X_w_in.y, sou.X_w_in);

connect(X_w_bac.y, sin.X_w_in);

end HeaterFanPressureDriven;

Heater and fan in series, model configured to not allow flow reversal

Information

This example demonstrates how to configure a model with a heater

and a fan that causes a pressure rise in the air stream.

The model is identical with

Annex60.Fluid.FMI.Validation.HeaterFan

except that reverse flow is not allowed due to the parameter

allowFlowReversal=false.

Consequently, the connectors for the fluid properties for the reverse flow

are removed, and the blocks on the right hand side of the model

Annex60.Fluid.FMI.Validation.HeaterFan

have been deleted.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| Boolean | use_p_in | false | = true to use a pressure from connector, false to output Medium.p_default |

| MassFlowRate | m_flow_nominal | Q_flow_nominal/1000/10 | Nominal mass flow rate [kg/s] |

| PressureDifference | dp_nominal | 2000 | Pressure [Pa] |

| HeatFlowRate | Q_flow_nominal | 1000 | Heat flow rate at u=1, positive for heating [W] |

Modelica definition

model HeaterFan_noReverseFlow

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

final parameter Boolean allowFlowReversal = false

;

parameter Boolean use_p_in = false

;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=Q_flow_nominal/1000/10

;

parameter Modelica.SIunits.PressureDifference dp_nominal(displayUnit="Pa")=2000

;

parameter Modelica.SIunits.HeatFlowRate Q_flow_nominal = 1000

;

ExportContainers.Examples.FMUs.Fan floMac(

redeclare final package Medium = Medium,

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

final allowFlowReversal=allowFlowReversal,

use_p_in=use_p_in) ;

ExportContainers.Examples.FMUs.HeaterCooler_u hea(

redeclare final package Medium = Medium,

m_flow_nominal=m_flow_nominal,

dp_nominal=dp_nominal,

Q_flow_nominal=Q_flow_nominal,

final allowFlowReversal=allowFlowReversal,

use_p_in=use_p_in) ;

Modelica.Blocks.Sources.Constant dp(k=1000) ;

Modelica.Blocks.Sources.Constant uHea(k=0.2) ;

Source_T sou(

redeclare package Medium = Medium,

final allowFlowReversal=allowFlowReversal,

use_p_in=use_p_in) ;

Modelica.Blocks.Sources.Constant m_flow(k=m_flow_nominal) ;

Modelica.Blocks.Sources.Constant pIn(k=100000) ;

Modelica.Blocks.Sources.Constant TIn(k=293.15) ;

Modelica.Blocks.Sources.Constant X_w_in(k=0.01) ;

Modelica.Blocks.Sources.Constant C[Medium.nC](

each k=0.01)

if

Medium.nC > 0 ;

equation

connect(uHea.y, hea.u);

connect(dp.y, floMac.dp_in);

connect(sou.outlet, hea.inlet);

connect(hea.outlet, floMac.inlet);

connect(m_flow.y, sou.m_flow_in);

connect(sou.p_in, pIn.y);

connect(TIn.y, sou.T_in);

connect(C.y, sou.C_in);

connect(X_w_in.y, sou.X_w_in);

end HeaterFan_noReverseFlow;

http://iea-annex60.org

Annex60.Fluid.FMI.Validation.FlowSplitter_u

Annex60.Fluid.FMI.Validation.FlowSplitter_u

Annex60.Fluid.FMI.Validation.HeaterFan

Annex60.Fluid.FMI.Validation.HeaterFan

Annex60.Fluid.FMI.Validation.HeaterFanPressureDriven

Annex60.Fluid.FMI.Validation.HeaterFanPressureDriven

Annex60.Fluid.FMI.Validation.HeaterFan_noReverseFlow

Annex60.Fluid.FMI.Validation.HeaterFan_noReverseFlow