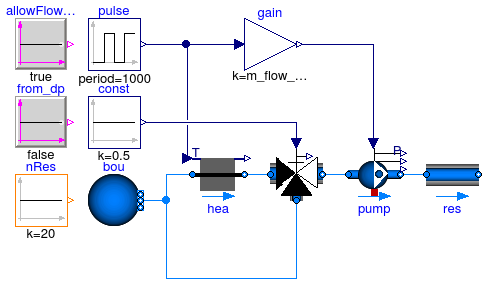

partial model Example1

extends Modelica.Icons.Example;

package Medium =

Modelica.Media.Water.ConstantPropertyLiquidWater;

parameter Real m_flow_nominal=0.1 ;

Annex60.Fluid.Sources.Boundary_pT bou(

redeclare package Medium = Medium,

nPorts=1) ;

Fluid.Movers.FlowControlled_m_flow pump(

redeclare package Medium = Medium,

m_flow_nominal=m_flow_nominal,

filteredSpeed=false,

allowFlowReversal=allowFlowReversal.k,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

nominalValuesDefineDefaultPressureCurve=true)

;

Annex60.Fluid.HeatExchangers.HeaterCooler_T hea(

redeclare package Medium = Medium,

dp_nominal=1000,

Q_flow_maxHeat=1000,

Q_flow_maxCool=0,

m_flow_nominal=m_flow_nominal,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

allowFlowReversal=allowFlowReversal.k) ;

Modelica.Blocks.Sources.Pulse pulse(period=1000) ;

Modelica.Blocks.Math.Gain gain(k=m_flow_nominal) ;

Annex60.Fluid.Actuators.Valves.ThreeWayLinear val(

redeclare package Medium = Medium,

m_flow_nominal=m_flow_nominal,

dpValve_nominal=1000,

l={0.002,0.002},

energyDynamics=Modelica.Fluid.Types.Dynamics.SteadyState,

filteredOpening=false,

portFlowDirection_1=

if allowFlowReversal.k

then Modelica.Fluid.Types.PortFlowDirection.Bidirectional

else Modelica.Fluid.Types.PortFlowDirection.Entering,

portFlowDirection_2=

if allowFlowReversal.k

then Modelica.Fluid.Types.PortFlowDirection.Bidirectional

else Modelica.Fluid.Types.PortFlowDirection.Leaving,

portFlowDirection_3=

if allowFlowReversal.k

then Modelica.Fluid.Types.PortFlowDirection.Bidirectional

else Modelica.Fluid.Types.PortFlowDirection.Entering)

;

Modelica.Blocks.Sources.Constant const(k=0.5) ;

Modelica.Blocks.Sources.BooleanConstant allowFlowReversal(k=true)

;

Annex60.Fluid.FixedResistances.PressureDrop[nRes.k] res(

redeclare package Medium = Medium,

each allowFlowReversal=allowFlowReversal.k,

each m_flow_nominal=m_flow_nominal,

each dp_nominal=1000,

each from_dp=from_dp.k) ;

Modelica.Blocks.Sources.IntegerConstant nRes(k=20)

;

Modelica.Blocks.Sources.BooleanConstant from_dp(k=false)

;

equation

connect(bou.ports[1],hea. port_a);

connect(pulse.y,hea. TSet);

connect(pump.m_flow_in, gain.y);

connect(gain.u,pulse. y);

connect(hea.port_b,val. port_1);

connect(val.port_2, pump.port_a);

connect(const.y,val. y);

connect(val.port_3,hea. port_a);

for i

in 1:nRes.k

loop

connect(pump.port_b, res[i].port_a);

end for;

end Example1;

Annex60.Fluid.Examples.Performance.BaseClasses.Example1

Annex60.Fluid.Examples.Performance.BaseClasses.Example1