| IEA EBC Annex 60 |

|

Package with models for fixed flow resistances

This package contains components models for fixed flow resistances. By fixed flow resistance, we mean resistances that do not change the flow coefficient

k = m ⁄ √ΔP.

For models of valves and air dampers, see Annex60.Fluid.Actuators. For models of flow resistances as part of the building constructions, see Annex60.Airflow.Multizone.

The model Annex60.Fluid.FixedResistances.PressureDrop is a fixed flow resistance that takes as parameter a nominal flow rate and a nominal pressure drop. The actual resistance is scaled using the above equation.

The model Annex60.Fluid.FixedResistances.HydraulicDiameter is a fixed flow resistance that takes as parameter a nominal flow rate and a hydraulic diameter. The actual resistance is scaled using the above equation.

The model Annex60.Fluid.FixedResistances.LosslessPipe is an ideal pipe segment with no pressure drop. It is primarily used in models in which the above pressure drop model need to be replaced by a model with no pressure drop.

The model Annex60.Fluid.FixedResistances.Junction can be used to model flow splitters or flow merges.

Extends from Modelica.Icons.VariantsPackage (Icon for package containing variants).

| Name | Description |

|---|---|

| Fixed flow resistance with hydraulic diameter and m_flow as parameter | |

| Flow splitter with fixed resistance at each port | |

| Pipe with no flow friction and no heat transfer | |

| Fixed flow resistance with dp and m_flow as parameter | |

| Collection of models that illustrate model use and test models | |

| Collection of validation models |

Annex60.Fluid.FixedResistances.HydraulicDiameter

Annex60.Fluid.FixedResistances.HydraulicDiameter

Fixed flow resistance with hydraulic diameter and m_flow as parameter

This is a model of a flow resistance with a fixed flow coefficient. The mass flow rate is computed as

ṁ = k √ΔP,

where

k is a constant and

ΔP is the pressure drop.

The constant k is equal to

k=m_flow_nominal/sqrt(dp_nominal),

where m_flow_nominal is a parameter.

In the region

abs(m_flow) < m_flow_turbulent,

the square root is replaced by a differentiable function

with finite slope.

The value of m_flow_turbulent is

computed as

m_flow_turbulent = eta_nominal*dh/4*π*ReC,

where

eta_nominal is the dynamic viscosity, obtained from

the medium model. The parameter

dh is the hydraulic diameter and

ReC=4000 is the critical Reynolds number, which both

can be set by the user.

By default, the pressure drop at nominal flow rate is computed as

dp_nominal = fac * dpStraightPipe_nominal,

where dpStraightPipe_nominal is a parameter that is automatically computed

based on the

nominal mass flow rate, hydraulic diameter, pipe roughness and medium properties.

The hydraulic diameter dh is by default

computed based on the flow velocity v_nominal and the nominal

mass flow rate m_flow_nominal. Hence, users should change the

default values of dh or v_nominal

if they are not applicable for their model.

The factor fac takes into account additional resistances such as

for bends. The default value of 2 can be changed by the user.

The parameter from_dp is used to determine

whether the mass flow rate is computed as a function of the

pressure drop (if from_dp=true), or vice versa.

This setting can affect the size of the nonlinear system of equations.

If the parameter linearized is set to true,

then the pressure drop is computed as a linear function of the

mass flow rate.

Setting allowFlowReversal=false can lead to simpler

equations. However, this should only be set to false

if one can guarantee that the flow never reverses its direction.

This can be difficult to guarantee, as pressure imbalance after

the initialization, or due to medium expansion and contraction,

can lead to reverse flow.

If the parameter

show_T is set to true,

then the model will compute the

temperature at its ports. Note that this can lead to state events

when the mass flow rate approaches zero,

which can increase computing time.

For more detailed models that compute the actual flow friction,

models from the package

Modelica.Fluid

can be used and combined with models from the

Annex60 library.

For a model that uses dp_nominal as a parameter rather than

geoemetric data, use

Annex60.Fluid.FixedResistances.PressureDrop.

The pressure drop is computed by calling a function in the package Buildings.Fluid.BaseClasses.FlowModels, This package contains regularized implementations of the equation

m = sign(Δp) k √ Δp

and its inverse function.

To decouple the energy equation from the mass equations, the pressure drop is a function of the mass flow rate, and not the volume flow rate. This leads to simpler equations.

Extends from Annex60.Fluid.FixedResistances.PressureDrop (Fixed flow resistance with dp and m_flow as parameter).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | PartialMedium | Medium in the component | |

| Length | dh | sqrt(4*m_flow_nominal/rho_de... | Hydraulic diameter (assuming a round cross section area) [m] |

| Length | length | Length of the pipe [m] | |

| Real | ReC | 4000 | Reynolds number where transition to turbulent starts |

| Length | roughness | 2.5e-5 | Absolute roughness of pipe, with a default for a smooth steel pipe (dummy if use_roughness = false) [m] |

| Real | fac | 2 | Factor to take into account resistance of bends etc., fac=dp_nominal/dpStraightPipe_nominal |

| Nominal condition | |||

| MassFlowRate | m_flow_nominal | Nominal mass flow rate [kg/s] | |

| PressureDifference | dp_nominal | fac*dpStraightPipe_nominal | Pressure drop at nominal mass flow rate [Pa] |

| Velocity | v_nominal | if rho_default < 500 then 1.... | Velocity at m_flow_nominal (used to compute default value for hydraulic diameter dh) [m/s] |

| Transition to laminar | |||

| Real | deltaM | eta_default*dh/4*Modelica.Co... | Fraction of nominal mass flow rate where transition to turbulent occurs |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = false to simplify equations, assuming, but not enforcing, no flow reversal |

| Advanced | |||

| Diagnostics | |||

| Boolean | show_T | false | = true, if actual temperature at port is computed |

| Boolean | from_dp | false | = true, use m_flow = f(dp) else dp = f(m_flow) |

| Boolean | homotopyInitialization | true | = true, use homotopy method |

| Boolean | linearized | false | = true, use linear relation between m_flow and dp for any flow rate |

| Type | Name | Description |

|---|---|---|

| FluidPort_a | port_a | Fluid connector a (positive design flow direction is from port_a to port_b) |

| FluidPort_b | port_b | Fluid connector b (positive design flow direction is from port_a to port_b) |

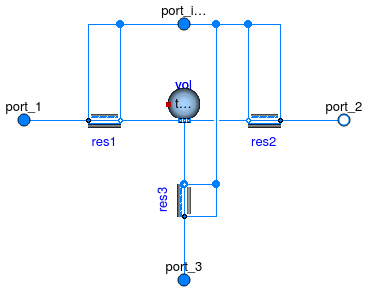

Annex60.Fluid.FixedResistances.Junction

Annex60.Fluid.FixedResistances.Junction

Flow splitter with fixed resistance at each port

Model of a flow junction with an optional fixed resistance in each flow leg and an optional mixing volume at the junction.

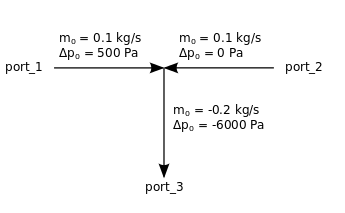

The pressure drop is implemented using the model Annex60.Fluid.FixedResistances.PressureDrop. If its nominal pressure drop is set to zero, then the pressure drop model will be removed. For example, the pressure drop declaration

m_flow_nominal={ 0.1, 0.1, -0.2},

dp_nominal = {500, 0, -6000}

would model a flow mixer that has the nominal flow rates and associated pressure drops

as shown in the figure below. Note that port_3 is set to negative values.

The negative values indicate that at the nominal conditions, fluid is leaving the component.

If

energyDynamics <> Modelica.Fluid.Types.Dynamics.SteadyState,

then at the flow junction, a fluid volume is modeled.

The fluid volume is implemented using the model

Annex60.Fluid.Delays.DelayFirstOrder.

The fluid volume has the size

V = sum(abs(m_flow_nominal[:])/3)*tau/rho_nominal

where tau is a parameter and rho_nominal is the density

of the medium in the volume at nominal condition.

Setting energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial

can help reducing the size of the nonlinear

system of equations.

Extends from Annex60.Fluid.BaseClasses.PartialThreeWayResistance (Flow splitter with partial resistance model at each port).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | PartialMedium | Medium in the component | |

| Nominal condition | |||

| MassFlowRate | m_flow_nominal[3] | Mass flow rate. Set negative at outflowing ports. [kg/s] | |

| Pressure | dp_nominal[3] | Pressure drop at nominal mass flow rate, set to zero or negative number at outflowing ports. [Pa] | |

| Transition to laminar | |||

| Real | deltaM | 0.3 | Fraction of nominal mass flow rate where transition to turbulent occurs |

| Dynamics | |||

| Equations | |||

| Dynamics | energyDynamics | Modelica.Fluid.Types.Dynamic... | Type of energy balance: dynamic (3 initialization options) or steady state |

| Dynamics | massDynamics | energyDynamics | Type of mass balance: dynamic (3 initialization options) or steady state |

| MassFlowRate | mDyn_flow_nominal | sum(abs(m_flow_nominal[:])/3) | Nominal mass flow rate for dynamic momentum and energy balance [kg/s] |

| Nominal condition | |||

| Time | tau | 10 | Time constant at nominal flow for dynamic energy and momentum balance [s] |

| Initialization | |||

| AbsolutePressure | p_start | Medium.p_default | Start value of pressure [Pa] |

| Temperature | T_start | Medium.T_default | Start value of temperature [K] |

| MassFraction | X_start[Medium.nX] | Medium.X_default | Start value of mass fractions m_i/m [kg/kg] |

| ExtraProperty | C_start[Medium.nC] | fill(0, Medium.nC) | Start value of trace substances |

| ExtraProperty | C_nominal[Medium.nC] | fill(1E-2, Medium.nC) | Nominal value of trace substances. (Set to typical order of magnitude.) |

| Advanced | |||

| Boolean | from_dp | true | = true, use m_flow = f(dp) else dp = f(m_flow) |

| PortFlowDirection | portFlowDirection_1 | Modelica.Fluid.Types.PortFlo... | Flow direction for port_1 |

| PortFlowDirection | portFlowDirection_2 | Modelica.Fluid.Types.PortFlo... | Flow direction for port_2 |

| PortFlowDirection | portFlowDirection_3 | Modelica.Fluid.Types.PortFlo... | Flow direction for port_3 |

| Boolean | linearized | false | = true, use linear relation between m_flow and dp for any flow rate |

| Boolean | homotopyInitialization | true | = true, use homotopy method |

| Type | Name | Description |

|---|---|---|

| FluidPort_a | port_1 | First port, typically inlet |

| FluidPort_b | port_2 | Second port, typically outlet |

| FluidPort_a | port_3 | Third port, can be either inlet or outlet |

Annex60.Fluid.FixedResistances.LosslessPipe

Annex60.Fluid.FixedResistances.LosslessPipe

Pipe with no flow friction and no heat transfer

Model of a pipe with no flow resistance, no heat loss and no transport delay.

This model can be used to replace a replaceable pipe model

in flow legs in which no friction should be modeled.

This is for example done in the outlet port of the

base class for three way valves,

Annex60.Fluid.Actuators.BaseClasses.PartialThreeWayValve.

Extends from Annex60.Fluid.Interfaces.PartialTwoPortInterface (Partial model transporting fluid between two ports without storing mass or energy).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | PartialMedium | Medium in the component | |

| Nominal condition | |||

| MassFlowRate | m_flow_nominal | Nominal mass flow rate [kg/s] | |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = false to simplify equations, assuming, but not enforcing, no flow reversal |

| Advanced | |||

| MassFlowRate | m_flow_small | 1E-4*abs(m_flow_nominal) | Small mass flow rate for regularization of zero flow [kg/s] |

| Diagnostics | |||

| Boolean | show_T | false | = true, if actual temperature at port is computed |

| Type | Name | Description |

|---|---|---|

| FluidPort_a | port_a | Fluid connector a (positive design flow direction is from port_a to port_b) |

| FluidPort_b | port_b | Fluid connector b (positive design flow direction is from port_a to port_b) |

Annex60.Fluid.FixedResistances.PressureDrop

Annex60.Fluid.FixedResistances.PressureDrop

Fixed flow resistance with dp and m_flow as parameter

Model of a flow resistance with a fixed flow coefficient. The mass flow rate is

ṁ = k √ΔP,

where

k is a constant and

ΔP is the pressure drop.

The constant k is equal to

k=m_flow_nominal/sqrt(dp_nominal),

where m_flow_nominal and dp_nominal

are parameters.

In the region

abs(m_flow) < m_flow_turbulent,

the square root is replaced by a differentiable function

with finite slope.

The value of m_flow_turbulent is

computed as

m_flow_turbulent = deltaM * abs(m_flow_nominal),

where deltaM=0.3 and

m_flow_nominal are parameters that can be set by the user.

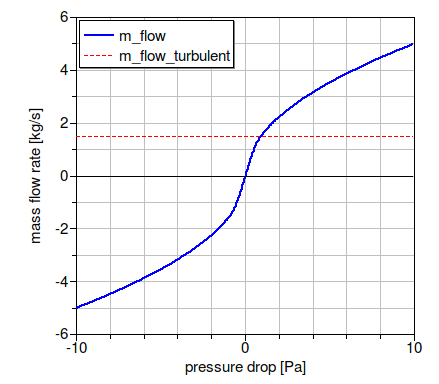

The figure below shows the pressure drop for the parameters

m_flow_nominal=5 kg/s,

dp_nominal=10 Pa and

deltaM=0.3.

The parameter from_dp is used to determine

whether the mass flow rate is computed as a function of the

pressure drop (if from_dp=true), or vice versa.

This setting can affect the size of the nonlinear system of equations.

If the parameter linearized is set to true,

then the pressure drop is computed as a linear function of the

mass flow rate.

Setting allowFlowReversal=false can lead to simpler

equations. However, this should only be set to false

if one can guarantee that the flow never reverses its direction.

This can be difficult to guarantee, as pressure imbalance after

the initialization, or due to medium expansion and contraction,

can lead to reverse flow.

If the parameter

show_T is set to true,

then the model will compute the

temperature at its ports. Note that this can lead to state events

when the mass flow rate approaches zero,

which can increase computing time.

For more detailed models that compute the actual flow friction,

models from the package

Modelica.Fluid

can be used and combined with models from the

Annex60 library.

For a model that uses the hydraulic parameter and flow velocity at nominal conditions as a parameter, use Annex60.Fluid.FixedResistances.HydraulicDiameter.

The pressure drop is computed by calling a function in the package Annex60.Fluid.BaseClasses.FlowModels, This package contains regularized implementations of the equation

m = sign(Δp) k √ Δp

and its inverse function.

To decouple the energy equation from the mass equations, the pressure drop is a function of the mass flow rate, and not the volume flow rate. This leads to simpler equations.

Extends from Annex60.Fluid.BaseClasses.PartialResistance (Partial model for a hydraulic resistance).

| Type | Name | Default | Description |

|---|---|---|---|

| replaceable package Medium | PartialMedium | Medium in the component | |

| MassFlowRate | m_flow_turbulent | if computeFlowResistance the... | Turbulent flow if |m_flow| >= m_flow_turbulent [kg/s] |

| Nominal condition | |||

| MassFlowRate | m_flow_nominal | Nominal mass flow rate [kg/s] | |

| PressureDifference | dp_nominal | Pressure drop at nominal mass flow rate [Pa] | |

| Transition to laminar | |||

| Real | deltaM | 0.3 | Fraction of nominal mass flow rate where transition to turbulent occurs |

| Assumptions | |||

| Boolean | allowFlowReversal | true | = false to simplify equations, assuming, but not enforcing, no flow reversal |

| Advanced | |||

| Diagnostics | |||

| Boolean | show_T | false | = true, if actual temperature at port is computed |

| Boolean | from_dp | false | = true, use m_flow = f(dp) else dp = f(m_flow) |

| Boolean | homotopyInitialization | true | = true, use homotopy method |

| Boolean | linearized | false | = true, use linear relation between m_flow and dp for any flow rate |

| Type | Name | Description |

|---|---|---|

| FluidPort_a | port_a | Fluid connector a (positive design flow direction is from port_a to port_b) |

| FluidPort_b | port_b | Fluid connector b (positive design flow direction is from port_a to port_b) |