Collection of models that illustrate model use and test models

Information

This package contains examples for the use of models that can be found in

Annex60.Fluid.Sensors.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

Package Content

| Name |

Description |

Density Density

|

Test model for the density sensor |

EnthalpyFlowRate EnthalpyFlowRate

|

Test model for the enthalpy flow rate sensors |

EntropyFlowRate EntropyFlowRate

|

Test model for the entropy flow rate sensors |

MassFraction MassFraction

|

Test model for the mass fraction sensor |

MoistAirEnthalpyFlowRate MoistAirEnthalpyFlowRate

|

Test model for the sensible and latent enthalpy flow rate sensors |

PPM PPM

|

Test model for the extra property sensor outputting PPM |

Pressure Pressure

|

Test model for the pressure sensor |

RelativeHumidity RelativeHumidity

|

Test model for relative humidity sensor |

SpecificEnthalpy SpecificEnthalpy

|

Test model for the enthalpy flow rate sensors |

SpecificEntropy SpecificEntropy

|

Test model for the entropy flow rate sensors |

TemperatureDryBulb TemperatureDryBulb

|

Test model for the dry bulb temperature sensor |

TemperatureWetBulb TemperatureWetBulb

|

Test model for the wet bulb temperature sensor |

TraceSubstances TraceSubstances

|

Test model for the extra property sensor |

Velocity Velocity

|

Test model for the flow velocity sensor |

VolumeFlowRate VolumeFlowRate

|

Test model for the volume flow rate sensor |

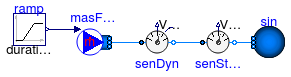

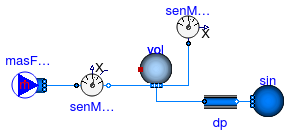

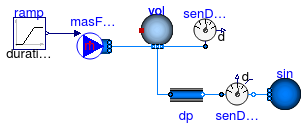

Test model for the density sensor

Information

This example tests the density sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model Density

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_T_in=false,

X={0.02,0.98},

nPorts=1,

use_m_flow_in=true) ;

Annex60.Fluid.Sensors.Density senDenVol(

redeclare package Medium = Medium) ;

Annex60.Fluid.MixingVolumes.MixingVolume vol(

redeclare package Medium = Medium,

V=1,

nPorts=3,

m_flow_nominal=10,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial) ;

Annex60.Fluid.FixedResistances.PressureDrop dp(

redeclare package Medium = Medium,

m_flow_nominal=10,

dp_nominal=200) ;

Annex60.Fluid.Sensors.DensityTwoPort senDenFlo(

redeclare package Medium = Medium,

m_flow_nominal=10) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-20,

offset=10,

duration=60);

equation

connect(masFloRat.ports[1], vol.ports[1]);

connect(vol.ports[2], dp.port_a);

connect(vol.ports[3], senDenVol.port);

connect(dp.port_b, senDenFlo.port_a);

connect(senDenFlo.port_b, sin.ports[1]);

connect(ramp.y, masFloRat.m_flow_in);

end Density;

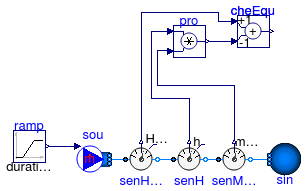

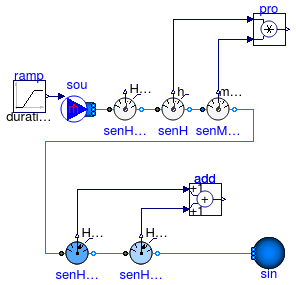

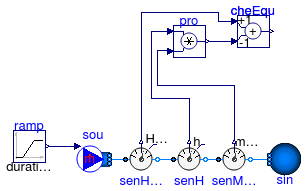

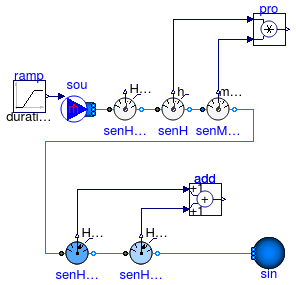

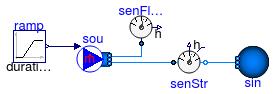

Test model for the enthalpy flow rate sensors

Information

This example tests the enthalpy flow rate sensor and the

specific enthalpy sensor.

The model compares the output of the enthalpy flow rate sensor with

the product of the output of the enthalpy and the mass flow rate sensor.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model EnthalpyFlowRate

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sensors.EnthalpyFlowRate senH_flow(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

Annex60.Fluid.Sources.MassFlowSource_T sou(

redeclare package Medium = Medium,

use_m_flow_in=true,

nPorts=1,

T=293.15) ;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

nPorts=1,

T=313.15) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-2,

offset=1,

duration=60) ;

Annex60.Fluid.Sensors.SpecificEnthalpyTwoPort senH(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

Annex60.Fluid.Sensors.MassFlowRate senM_flow(

redeclare package Medium = Medium) ;

Modelica.Blocks.Math.Add cheEqu(k2=-1)

;

Modelica.Blocks.Math.Product pro ;

equation

connect(ramp.y, sou.m_flow_in);

connect(sou.ports[1], senH_flow.port_a);

connect(senH_flow.port_b, senH.port_a);

connect(senH.port_b, senM_flow.port_a);

connect(senM_flow.port_b, sin.ports[1]);

connect(senH_flow.H_flow,cheEqu. u1);

connect(senH.h_out, pro.u1);

connect(senM_flow.m_flow, pro.u2);

connect(pro.y,cheEqu. u2);

end EnthalpyFlowRate;

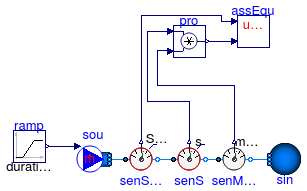

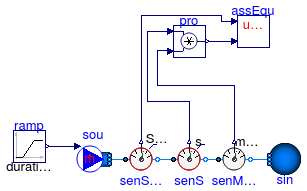

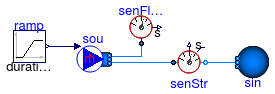

Test model for the entropy flow rate sensors

Information

This example tests the entropy flow rate sensor and the

specific entropy sensor.

The model compares the output of the entropy flow rate sensor with

the product of the output of the entropy and the mass flow rate sensor.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model EntropyFlowRate

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sensors.EntropyFlowRate senS_flow(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

Annex60.Fluid.Sources.MassFlowSource_T sou(

redeclare package Medium = Medium,

use_m_flow_in=true,

nPorts=1,

T=293.15) ;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

nPorts=1,

T=313.15) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-2,

offset=1,

duration=60) ;

Annex60.Fluid.Sensors.SpecificEntropyTwoPort senS(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

Annex60.Fluid.Sensors.MassFlowRate senM_flow(

redeclare package Medium = Medium) ;

Annex60.Utilities.Diagnostics.AssertEquality assEqu

;

Modelica.Blocks.Math.Product pro ;

equation

connect(ramp.y, sou.m_flow_in);

connect(sou.ports[1],senS_flow. port_a);

connect(senS_flow.port_b,senS. port_a);

connect(senS.port_b, senM_flow.port_a);

connect(senM_flow.port_b, sin.ports[1]);

connect(senM_flow.m_flow, pro.u2);

connect(pro.y, assEqu.u2);

connect(senS_flow.S_flow, assEqu.u1);

connect(senS.s, pro.u1);

end EntropyFlowRate;

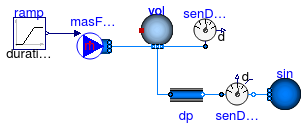

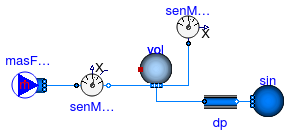

Test model for the mass fraction sensor

Information

This example tests the mass fraction sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model MassFraction

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

nPorts=1,

T=293.15) ;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

X={0.02,0.98},

m_flow=10,

nPorts=1) ;

Annex60.Fluid.Sensors.MassFraction senMasFra2(

redeclare package Medium = Medium) ;

Annex60.Fluid.MixingVolumes.MixingVolume vol(

redeclare package Medium = Medium,

V=1,

nPorts=3,

m_flow_nominal=10,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial) ;

Annex60.Fluid.FixedResistances.PressureDrop dp(

redeclare package Medium = Medium,

m_flow_nominal=10,

dp_nominal=200) ;

Annex60.Fluid.Sensors.MassFractionTwoPort senMasFra1(

redeclare package Medium = Medium, m_flow_nominal=10)

;

equation

connect(dp.port_b, sin.ports[1]);

connect(masFloRat.ports[1], senMasFra1.port_a);

connect(senMasFra1.port_b, vol.ports[1]);

connect(vol.ports[2], dp.port_a);

connect(vol.ports[3], senMasFra2.port);

end MassFraction;

Test model for the sensible and latent enthalpy flow rate sensors

Information

This example tests the sensible and latent enthalpy sensors.

It compares the output from the enthalpy sensor with the sum of the

sensible and latent enthalpy sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model MoistAirEnthalpyFlowRate

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

Annex60.Fluid.Sensors.EnthalpyFlowRate senH_flow(

redeclare package Medium = Medium,

m_flow_nominal=1) ;

Annex60.Fluid.Sources.MassFlowSource_T sou(

redeclare package Medium = Medium,

use_m_flow_in=true,

nPorts=1,

T=293.15) ;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

nPorts=1,

X={0.02,0.98},

T=313.15) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-2,

offset=1,

duration=60);

Annex60.Fluid.Sensors.SpecificEnthalpyTwoPort senH(

redeclare package Medium = Medium,

m_flow_nominal=1) ;

Annex60.Fluid.Sensors.MassFlowRate senM_flow(

redeclare package Medium = Medium) ;

Modelica.Blocks.Math.Product pro ;

Annex60.Fluid.Sensors.LatentEnthalpyFlowRate senHLat_flow(

redeclare package Medium = Medium,

m_flow_nominal=1) ;

Annex60.Fluid.Sensors.SensibleEnthalpyFlowRate senHSen_flow(

redeclare package Medium = Medium, m_flow_nominal=1)

;

Modelica.Blocks.Math.Add add

;

equation

connect(ramp.y, sou.m_flow_in);

connect(sou.ports[1], senH_flow.port_a);

connect(senH_flow.port_b, senH.port_a);

connect(senH.port_b, senM_flow.port_a);

connect(senH.h_out, pro.u1);

connect(senM_flow.m_flow, pro.u2);

connect(senHLat_flow.H_flow, add.u1);

connect(senHSen_flow.H_flow, add.u2);

connect(senM_flow.port_b, senHLat_flow.port_a);

connect(senHLat_flow.port_b, senHSen_flow.port_a);

connect(senHSen_flow.port_b, sin.ports[1]);

end MoistAirEnthalpyFlowRate;

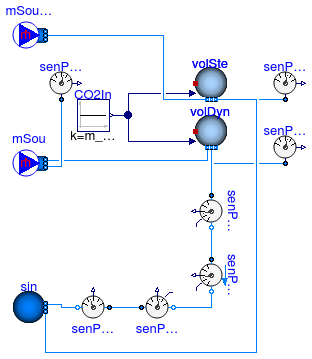

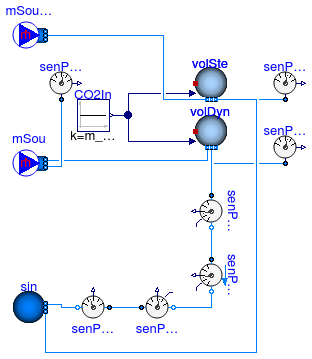

Test model for the extra property sensor outputting PPM

Information

This example tests the sensors that measure trace substances

using an output in parts per million.

Various configurations with and without flow reversal

and with or without dynamics are tested.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | volDyn.V*senPPMTwoPort.tau*3... | Mass flow rate into and out of the volume [kg/s] |

Modelica definition

model PPM

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air(extraPropertiesNames={"CO2"})

;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal = volDyn.V*senPPMTwoPort.tau*3*rho_default

;

Annex60.Fluid.MixingVolumes.MixingVolume volDyn(

redeclare package Medium = Medium,

nPorts=3,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

V=1,

use_C_flow=true,

massDynamics=Modelica.Fluid.Types.Dynamics.SteadyState,

m_flow_nominal=m_flow_nominal) ;

Annex60.Fluid.Sources.MassFlowSource_T mSou(

redeclare package Medium = Medium,

nPorts=2,

m_flow=m_flow_nominal) ;

Annex60.Fluid.Sources.FixedBoundary sin(

redeclare package Medium = Medium, nPorts=2)

;

Annex60.Fluid.Sensors.PPM senPPMVol(

redeclare package Medium = Medium)

;

Modelica.Blocks.Sources.Constant CO2In(k=m_flow_nominal/1000)

;

Annex60.Fluid.Sensors.PPMTwoPort senPPMTwoPort(

redeclare package Medium = Medium,

allowFlowReversal=true,

m_flow_nominal=m_flow_nominal) ;

Annex60.Fluid.Sensors.PPM senPPMIn(

redeclare package Medium = Medium)

;

Annex60.Fluid.Sensors.PPMTwoPort senPPMNoRev(

redeclare package Medium = Medium,

allowFlowReversal=false,

m_flow_nominal=m_flow_nominal) ;

Annex60.Fluid.Sensors.PPMTwoPort senPPMRev(

redeclare package Medium = Medium,

allowFlowReversal=true,

m_flow_nominal=m_flow_nominal) ;

Annex60.Fluid.Sensors.PPMTwoPort senPPMSta(

redeclare package Medium = Medium,

allowFlowReversal=true,

tau=0,

m_flow_nominal=m_flow_nominal) ;

protected

final parameter Medium.ThermodynamicState state_default =

Medium.setState_pTX(

T=Medium.T_default,

p=Medium.p_default,

X=Medium.X_default[1:Medium.nXi]) ;

final parameter Modelica.SIunits.Density rho_default=

Medium.density(

state=state_default) ;

public

Annex60.Fluid.MixingVolumes.MixingVolume volSte(

redeclare package Medium = Medium,

nPorts=3,

V=1,

use_C_flow=true,

massDynamics=Modelica.Fluid.Types.Dynamics.SteadyState,

m_flow_nominal=m_flow_nominal,

energyDynamics=Modelica.Fluid.Types.Dynamics.SteadyState)

;

Annex60.Fluid.Sensors.PPM senPPMVol2(

redeclare package Medium = Medium)

;

Annex60.Fluid.Sources.MassFlowSource_T mSouSta(

redeclare package Medium = Medium,

nPorts=1,

m_flow=m_flow_nominal) ;

equation

connect(mSou.ports[1], volDyn.ports[1]);

connect(CO2In.y, volDyn.C_flow[1]);

connect(senPPMVol.port, volDyn.ports[2]);

connect(senPPMIn.port, mSou.ports[2]);

connect(senPPMTwoPort.port_a, volDyn.ports[3]);

connect(senPPMNoRev.port_a, senPPMTwoPort.port_b);

connect(senPPMRev.port_b, senPPMNoRev.port_b);

connect(senPPMSta.port_a, senPPMRev.port_a);

connect(senPPMSta.port_b, sin.ports[1]);

connect(CO2In.y,volSte. C_flow[1]);

connect(volSte.ports[1], senPPMVol2.port);

connect(volSte.ports[2], sin.ports[2]);

connect(mSouSta.ports[1], volSte.ports[3]);

end PPM;

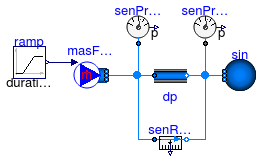

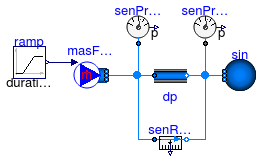

Test model for the pressure sensor

Information

This example tests the pressure sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model Pressure

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_T_in=false,

X={0.02,0.98},

use_m_flow_in=true,

nPorts=1) ;

Annex60.Fluid.FixedResistances.PressureDrop dp(

redeclare package Medium = Medium,

m_flow_nominal=10,

dp_nominal=200) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-20,

offset=10,

duration=1);

Annex60.Fluid.Sensors.Pressure senPre_a(

redeclare package Medium = Medium)

;

Annex60.Fluid.Sensors.Pressure senPre_b(

redeclare package Medium = Medium)

;

Annex60.Fluid.Sensors.RelativePressure senRelPre(

redeclare package Medium = Medium) ;

equation

connect(ramp.y, masFloRat.m_flow_in);

connect(masFloRat.ports[1], dp.port_a);

connect(dp.port_b, sin.ports[1]);

connect(senPre_a.port, dp.port_a);

connect(senPre_b.port, dp.port_b);

connect(senRelPre.port_a, dp.port_a);

connect(senRelPre.port_b, dp.port_b);

end Pressure;

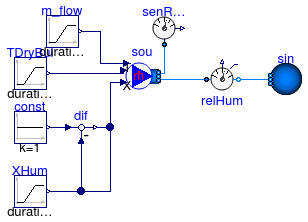

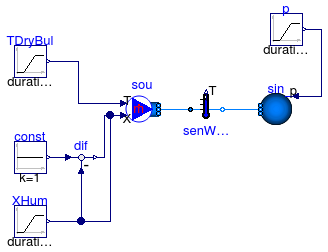

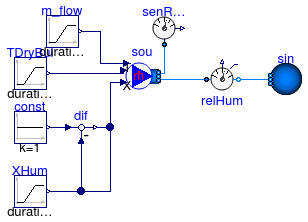

Test model for relative humidity sensor

Information

This example tests the relative humidity sensors.

Note that the sensor with one port always measures the humidity

as if the flow would be leaving the source.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model RelativeHumidity

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

use_p_in=false,

T=293.15,

nPorts=1);

Annex60.Fluid.Sources.MassFlowSource_T sou(

redeclare package Medium = Medium,

m_flow=1,

use_T_in=true,

use_X_in=true,

use_m_flow_in=true,

nPorts=2) ;

Modelica.Blocks.Sources.Ramp TDryBul(

height=10,

offset=273.15 + 30,

duration=120) ;

Modelica.Blocks.Sources.Ramp XHum(

duration=1,

height=(0.0133 - 0.0175),

offset=0.0175) ;

Modelica.Blocks.Sources.Constant const(k=1) ;

Modelica.Blocks.Math.Feedback dif

;

Annex60.Fluid.Sensors.RelativeHumidity senRelHum(

redeclare package Medium = Medium)

;

Modelica.Blocks.Sources.Ramp m_flow(

height=-2,

offset=1,

duration=500) ;

Annex60.Fluid.Sensors.RelativeHumidityTwoPort relHum(

redeclare package Medium = Medium, m_flow_nominal=1,

initType=Modelica.Blocks.Types.Init.InitialState)

;

equation

connect(TDryBul.y, sou.T_in);

connect(const.y, dif.u1);

connect(XHum.y, dif.u2);

connect(XHum.y, sou.X_in[1]);

connect(dif.y, sou.X_in[2]);

connect(m_flow.y, sou.m_flow_in);

connect(relHum.port_b, sin.ports[1]);

connect(senRelHum.port, sou.ports[1]);

connect(sou.ports[2], relHum.port_a);

end RelativeHumidity;

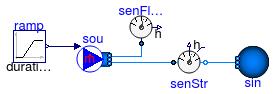

Test model for the enthalpy flow rate sensors

Information

This example tests the specific enthalpy sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model SpecificEnthalpy

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sources.MassFlowSource_h sou(

redeclare package Medium = Medium,

use_m_flow_in=true,

use_h_in=false,

nPorts=2) ;

Annex60.Fluid.Sources.Boundary_ph sin(

redeclare package Medium = Medium,

use_h_in=false,

h=20,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-2,

offset=1,

duration=60);

Annex60.Fluid.Sensors.SpecificEnthalpy senFloSou(

redeclare package Medium = Medium) ;

Annex60.Fluid.Sensors.SpecificEnthalpyTwoPort senStr(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

equation

connect(ramp.y, sou.m_flow_in);

connect(sou.ports[1], senFloSou.port);

connect(sou.ports[2], senStr.port_a);

connect(senStr.port_b, sin.ports[1]);

end SpecificEnthalpy;

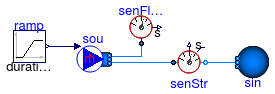

Test model for the entropy flow rate sensors

Information

This example tests the specific entropy sensors.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model SpecificEntropy

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sources.MassFlowSource_h sou(

redeclare package Medium = Medium,

use_m_flow_in=true,

use_h_in=false,

nPorts=2) ;

Annex60.Fluid.Sources.Boundary_ph sin(

redeclare package Medium = Medium,

use_h_in=false,

h=20,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-2,

offset=1,

duration=60);

Annex60.Fluid.Sensors.SpecificEntropy senFloSou(

redeclare package Medium = Medium) ;

Annex60.Fluid.Sensors.SpecificEntropyTwoPort senStr(

redeclare package Medium = Medium,

m_flow_nominal=2) ;

equation

connect(ramp.y, sou.m_flow_in);

connect(sou.ports[1], senFloSou.port);

connect(sou.ports[2], senStr.port_a);

connect(senStr.port_b, sin.ports[1]);

end SpecificEntropy;

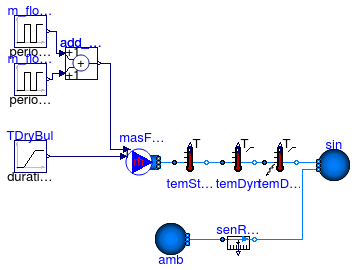

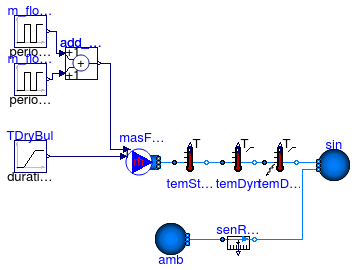

Test model for the dry bulb temperature sensor

Information

This example tests the dry bulb temperature sensors.

One sensor is configured to be a steady-state model,

a second sensor is configured to be a dynamic sensor and

the third sensors is a dynamic sensor with heat transfer.

There is also a sensor that measures the temperature difference.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model TemperatureDryBulb

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Annex60.Fluid.Sources.Boundary_pT amb(

redeclare package Medium = Medium,

T=298.15,

nPorts=1)

;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_T_in=true,

use_m_flow_in=true,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp TDryBul(

height=10,

duration=1,

offset=273.15 + 30) ;

Annex60.Fluid.Sensors.TemperatureTwoPort temSteSta(

redeclare package Medium = Medium,

m_flow_nominal=2,

tau=0) ;

Modelica.Blocks.Sources.Pulse m_flow1(

period=30,

offset=0,

amplitude=-1) ;

Annex60.Fluid.Sensors.TemperatureTwoPort temDyn(

redeclare package Medium = Medium,

m_flow_nominal=2,

initType=Modelica.Blocks.Types.Init.InitialState,

T_start=293.15) ;

RelativeTemperature senRelTem(

redeclare package Medium = Medium)

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

T=293.15,

nPorts=2) ;

Annex60.Fluid.Sensors.TemperatureTwoPort temDynLoss(

redeclare package Medium = Medium,

m_flow_nominal=2,

initType=Modelica.Blocks.Types.Init.InitialState,

transferHeat=true,

T_start=293.15,

TAmb=293.15,

tauHeaTra=30) ;

Modelica.Blocks.Math.Add add_m_flow

;

Modelica.Blocks.Sources.Pulse m_flow2(

amplitude=1,

offset=0,

period=45) ;

equation

connect(TDryBul.y, masFloRat.T_in);

connect(masFloRat.ports[1], temSteSta.port_a);

connect(temSteSta.port_b, temDyn.port_a);

connect(amb.ports[1], senRelTem.port_a);

connect(temDyn.port_b, temDynLoss.port_a);

connect(masFloRat.m_flow_in, add_m_flow.y);

connect(add_m_flow.u1, m_flow1.y);

connect(m_flow2.y, add_m_flow.u2);

connect(sin.ports[1], temDynLoss.port_b);

connect(sin.ports[2], senRelTem.port_b);

end TemperatureDryBulb;

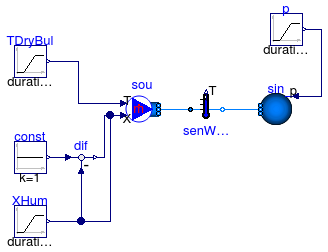

Test model for the wet bulb temperature sensor

Information

This example tests the wet bulb temperature sensor.

The problem setup is such that the moisture concentration and

the dry bulb temperature are varied simultaneously in such a way

that the wet bulb temperature remains close to a constant value.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model TemperatureWetBulb

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

Modelica.Blocks.Sources.Ramp p(

duration=1,

offset=101325,

height=250) ;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium=Medium,

use_p_in=true,

nPorts=1,

T=293.15) ;

Annex60.Fluid.Sensors.TemperatureWetBulbTwoPort senWetBul(

redeclare package Medium=Medium,

m_flow_nominal=1,

tau=0) ;

Annex60.Fluid.Sources.MassFlowSource_T sou(

redeclare package Medium = Medium,

m_flow=1,

use_T_in=true,

use_X_in=true,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp TDryBul(

height=10,

offset=273.15 + 30,

duration=50) ;

Modelica.Blocks.Sources.Ramp XHum(

height=(0.0133 - 0.0175),

offset=0.0175,

duration=50) ;

Modelica.Blocks.Sources.Constant const(k=1);

Modelica.Blocks.Math.Feedback dif

;

equation

connect(TDryBul.y, sou.T_in);

connect(const.y, dif.u1);

connect(XHum.y, dif.u2);

connect(XHum.y, sou.X_in[1]);

connect(dif.y, sou.X_in[2]);

connect(p.y, sin.p_in);

connect(sou.ports[1], senWetBul.port_a);

connect(senWetBul.port_b, sin.ports[1]);

end TemperatureWetBulb;

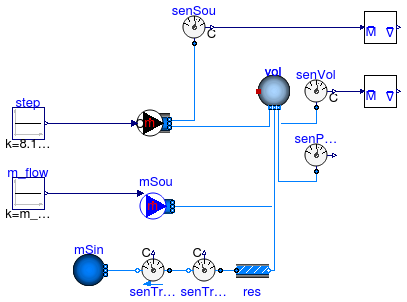

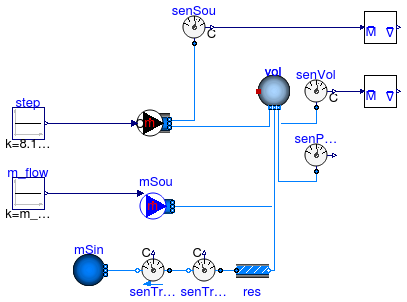

Test model for the extra property sensor

Information

This example tests the sensors that measure trace substances.

A CO2 mass flow rate of 8.18E-8 kg/kg is added to the

volume. The volume also has a fresh air mass flow rate and

an exhaust air mass flow rate. The initial CO2 concentration

of the volume is 0 kg/kg.

Note that the fresh air supply has zero carbon dioxide concentration.

Therefore, if it were outside air, then all concentrations are relative

to the outside air concentration.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | 15*1.2/3600 | Mass flow rate into and out of the volume [kg/s] |

Modelica definition

model TraceSubstances

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air(extraPropertiesNames={"CO2"})

;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal = 15*1.2/3600

;

MixingVolumes.MixingVolume vol(

redeclare package Medium = Medium,

V=2*3*3,

m_flow_nominal=1E-6,

nPorts=5,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial) ;

Sources.TraceSubstancesFlowSource sou(

redeclare package Medium = Medium,

nPorts=2,

use_m_flow_in=true) ;

Modelica.Blocks.Sources.Constant step(k=8.18E-6) ;

Annex60.Fluid.Sensors.TraceSubstances senVol(

redeclare package Medium = Medium) ;

Annex60.Fluid.Sensors.TraceSubstances senSou(

redeclare package Medium = Medium,

substanceName="CO2") ;

Modelica.Blocks.Sources.Constant m_flow(k=m_flow_nominal)

;

Annex60.Fluid.Sources.MassFlowSource_T mSou(

redeclare package Medium = Medium,

use_m_flow_in=true,

nPorts=1) ;

Sources.FixedBoundary mSin(

redeclare package Medium = Medium, nPorts=1) ;

Annex60.Fluid.Sensors.Conversions.To_VolumeFraction masFraSou(

MMMea=Modelica.Media.IdealGases.Common.SingleGasesData.CO2.MM)

;

Annex60.Fluid.Sensors.Conversions.To_VolumeFraction masFraVol(

MMMea=Modelica.Media.IdealGases.Common.SingleGasesData.CO2.MM)

;

Annex60.Fluid.Sensors.TraceSubstancesTwoPort senTraSub(

redeclare package Medium = Medium,

m_flow_nominal=m_flow_nominal,

tau=0) ;

FixedResistances.PressureDrop res(

redeclare package Medium = Medium,

dp_nominal=10,

m_flow_nominal=0.005,

linearized=true);

Annex60.Fluid.Sensors.TraceSubstancesTwoPort senTraSubNoFlorRev(

redeclare package Medium = Medium,

m_flow_nominal=m_flow_nominal,

allowFlowReversal=false,

tau=0) ;

Annex60.Fluid.Sensors.PPM senPPM(

redeclare package Medium = Medium)

;

equation

connect(m_flow.y, mSou.m_flow_in);

connect(senSou.C, masFraSou.m);

connect(senVol.C, masFraVol.m);

connect(sou.ports[1], senSou.port);

connect(step.y, sou.m_flow_in);

connect(sou.ports[2], vol.ports[1]);

connect(mSou.ports[1], vol.ports[2]);

connect(res.port_a, senTraSub.port_a);

connect(res.port_b, vol.ports[3]);

connect(senVol.port, vol.ports[4]);

connect(senTraSubNoFlorRev.port_a, senTraSub.port_b);

connect(senTraSubNoFlorRev.port_b, mSin.ports[1]);

connect(senPPM.port, vol.ports[5]);

end TraceSubstances;

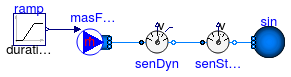

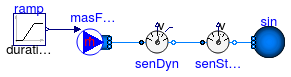

Test model for the flow velocity sensor

Information

This example tests the flow velocity sensor.

One sensor is configured to be steady-state, and the other is

configured to be dynamic.

Note that steady-state sensors can lead to numerical problems

if used incorrectly.

See

Annex60.Fluid.Sensors.UsersGuide for an explanation.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| Area | A | 0.1*0.1/4*Modelica.Constants... | Cross sectional area of flow channel [m2] |

Modelica definition

model Velocity

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air ;

parameter Modelica.SIunits.Area A = 0.1*0.1/4*Modelica.Constants.pi

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_T_in=false,

X={0.02,0.98},

use_m_flow_in=true,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp ramp(

duration=60,

height=-0.2,

offset=0.1) ;

Annex60.Fluid.Sensors.Velocity senDyn(

redeclare package Medium = Medium,

m_flow_nominal=10,

A=A) ;

Annex60.Fluid.Sensors.Velocity senSteSta(

redeclare package Medium = Medium,

m_flow_nominal=10,

tau=0,

A=A) ;

equation

connect(ramp.y, masFloRat.m_flow_in);

connect(masFloRat.ports[1], senDyn.port_a);

connect(senDyn.port_b, senSteSta.port_a);

connect(senSteSta.port_b, sin.ports[1]);

end Velocity;

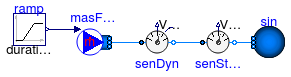

Test model for the volume flow rate sensor

Information

This example tests the volume flow rate sensor.

One sensor is configured to be steady-state, and the other is

configured to be dynamic.

Note that steady-state sensors can lead to numerical problems

if used incorrectly.

See

Annex60.Fluid.Sensors.UsersGuide for an explanation.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model VolumeFlowRate

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T masFloRat(

redeclare package Medium = Medium,

use_T_in=false,

X={0.02,0.98},

use_m_flow_in=true,

nPorts=1) ;

Modelica.Blocks.Sources.Ramp ramp(

height=-20,

offset=10,

duration=60);

Annex60.Fluid.Sensors.VolumeFlowRate senDyn(

redeclare package Medium = Medium,

m_flow_nominal=10)

;

Annex60.Fluid.Sensors.VolumeFlowRate senSteSta(

redeclare package Medium = Medium,

m_flow_nominal=10,

tau=0) ;

equation

connect(ramp.y, masFloRat.m_flow_in);

connect(masFloRat.ports[1], senDyn.port_a);

connect(senDyn.port_b, senSteSta.port_a);

connect(senSteSta.port_b, sin.ports[1]);

end VolumeFlowRate;

http://iea-annex60.org

Annex60.Fluid.Sensors.Examples.Density

Annex60.Fluid.Sensors.Examples.Density

Annex60.Fluid.Sensors.Examples.EnthalpyFlowRate

Annex60.Fluid.Sensors.Examples.EnthalpyFlowRate

Annex60.Fluid.Sensors.Examples.EntropyFlowRate

Annex60.Fluid.Sensors.Examples.EntropyFlowRate

Annex60.Fluid.Sensors.Examples.MassFraction

Annex60.Fluid.Sensors.Examples.MassFraction

Annex60.Fluid.Sensors.Examples.MoistAirEnthalpyFlowRate

Annex60.Fluid.Sensors.Examples.MoistAirEnthalpyFlowRate

Annex60.Fluid.Sensors.Examples.PPM

Annex60.Fluid.Sensors.Examples.PPM

Annex60.Fluid.Sensors.Examples.Pressure

Annex60.Fluid.Sensors.Examples.Pressure

Annex60.Fluid.Sensors.Examples.RelativeHumidity

Annex60.Fluid.Sensors.Examples.RelativeHumidity

Annex60.Fluid.Sensors.Examples.SpecificEnthalpy

Annex60.Fluid.Sensors.Examples.SpecificEnthalpy

Annex60.Fluid.Sensors.Examples.SpecificEntropy

Annex60.Fluid.Sensors.Examples.SpecificEntropy

Annex60.Fluid.Sensors.Examples.TemperatureDryBulb

Annex60.Fluid.Sensors.Examples.TemperatureDryBulb

Annex60.Fluid.Sensors.Examples.TemperatureWetBulb

Annex60.Fluid.Sensors.Examples.TemperatureWetBulb

Annex60.Fluid.Sensors.Examples.TraceSubstances

Annex60.Fluid.Sensors.Examples.TraceSubstances

Annex60.Fluid.Sensors.Examples.Velocity

Annex60.Fluid.Sensors.Examples.Velocity

Annex60.Fluid.Sensors.Examples.VolumeFlowRate

Annex60.Fluid.Sensors.Examples.VolumeFlowRate