Collection of models that illustrate model use and test models

Information

This package contains examples for the use of models that can be found in

Annex60.Fluid.Interfaces.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

Package Content

| Name |

Description |

ConservationEquation ConservationEquation

|

Model that tests the conservation equation |

FourPortHeatMassExchanger FourPortHeatMassExchanger

|

FourPortHeatMassExchanger example model |

HeaterCooler_u HeaterCooler_u

|

Model that tests a heat exchanger model with reverse flow |

Humidifier_u Humidifier_u

|

|

PrescribedOutletState PrescribedOutletState

|

Test model for prescribed outlet state |

ReverseFlowHumidifier ReverseFlowHumidifier

|

Model that tests the reverse flow for a humidifier |

ReverseFlowMassExchanger ReverseFlowMassExchanger

|

Model that tests the reverse flow for a mass exchanger |

StaticTwoPortConservationEquation StaticTwoPortConservationEquation

|

Model that tests the static two port conservation equation |

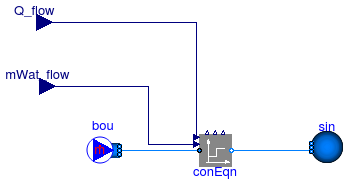

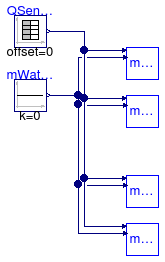

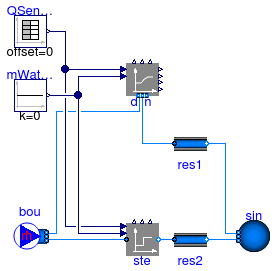

Model that tests the conservation equation

Information

Model that tests the conservation equations that are used

for the heat and mass balance.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model ConservationEquation

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Water ;

Annex60.Fluid.Interfaces.ConservationEquation dyn(

redeclare package Medium =

Medium, energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

nPorts=2,

fluidVolume=0.01,

use_mWat_flow=true) ;

Annex60.Fluid.Interfaces.StaticTwoPortConservationEquation ste(

redeclare package Medium = Medium,

m_flow_nominal=0.01,

show_T=true,

use_mWat_flow=true) ;

Modelica.Blocks.Sources.Constant mWat_flow(k=0)

;

Modelica.Blocks.Sources.TimeTable QSen_flow(startTime=0, table=[

0,-100;

900,-100;

900,0;

1800,0;

1800,100])

;

Annex60.Fluid.Sources.Boundary_pT sin(

nPorts=2,

use_p_in=false,

redeclare package Medium = Medium,

p=101325,

T=283.15);

Annex60.Fluid.FixedResistances.PressureDrop res1(

from_dp=true,

redeclare package Medium = Medium,

m_flow_nominal=0.01,

dp_nominal=100) ;

Annex60.Fluid.Sources.MassFlowSource_T bou(

nPorts=2,

redeclare package Medium = Medium,

m_flow=0.01) ;

Annex60.Fluid.FixedResistances.PressureDrop res2(

from_dp=true,

redeclare package Medium = Medium,

m_flow_nominal=0.01,

dp_nominal=100) ;

equation

connect(QSen_flow.y, dyn.Q_flow);

connect(mWat_flow.y, dyn.mWat_flow);

connect(bou.ports[1], dyn.ports[1]);

connect(res1.port_b, sin.ports[1]);

connect(QSen_flow.y, ste.Q_flow);

connect(mWat_flow.y, ste.mWat_flow);

connect(res2.port_b, sin.ports[2]);

connect(ste.port_a, bou.ports[2]);

connect(ste.port_b, res2.port_a);

connect(dyn.ports[2], res1.port_a);

end ConservationEquation;

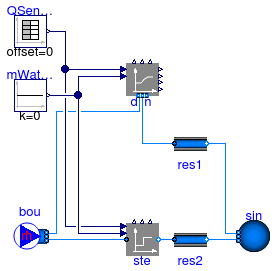

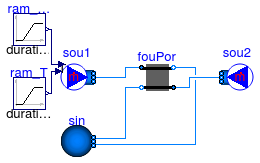

FourPortHeatMassExchanger example model

Information

This example model demonstrates the used of the

FourPortHeatMassExchanger model.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | 1 | Nominal mass flow rate [kg/s] |

Modelica definition

model FourPortHeatMassExchanger

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Water;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=1

;

Annex60.Fluid.Interfaces.FourPortHeatMassExchanger fouPor(

redeclare package Medium1 = Medium,

redeclare package Medium2 = Medium,

m1_flow_nominal=m_flow_nominal,

m2_flow_nominal=m_flow_nominal,

dp1_nominal=0,

dp2_nominal=0,

tau1=1,

tau2=1,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Sources.Boundary_pT sin(nPorts=2,

redeclare package Medium = Medium)

;

Sources.MassFlowSource_T sou1(

nPorts=1,

redeclare package Medium = Medium,

use_m_flow_in=true,

use_T_in=true) ;

Sources.MassFlowSource_T sou2(

nPorts=1,

redeclare package Medium = Medium,

m_flow=1,

T=283.15) ;

Modelica.Blocks.Sources.Ramp ram_T(

height=10,

offset=273.15,

duration=5) ;

Modelica.Blocks.Sources.Ramp ram_m_flow(

height=-2,

offset=1,

duration=5) ;

equation

connect(sin.ports[1], fouPor.port_b2);

connect(fouPor.port_b1, sin.ports[2]);

connect(sou1.ports[1], fouPor.port_a1);

connect(sou2.ports[1], fouPor.port_a2);

connect(ram_m_flow.y, sou1.m_flow_in);

connect(ram_T.y, sou1.T_in);

end FourPortHeatMassExchanger;

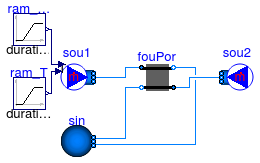

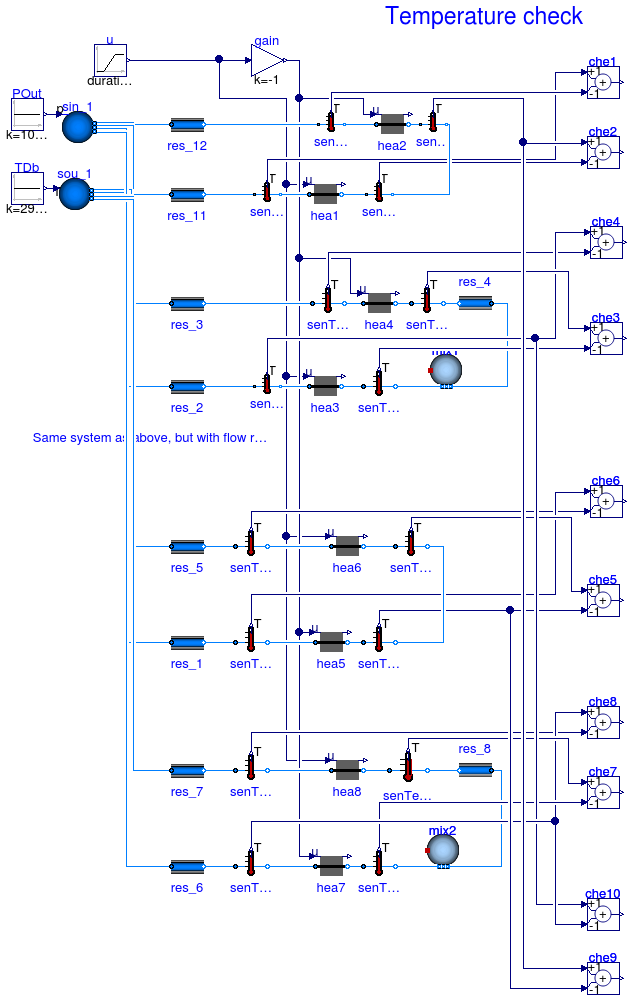

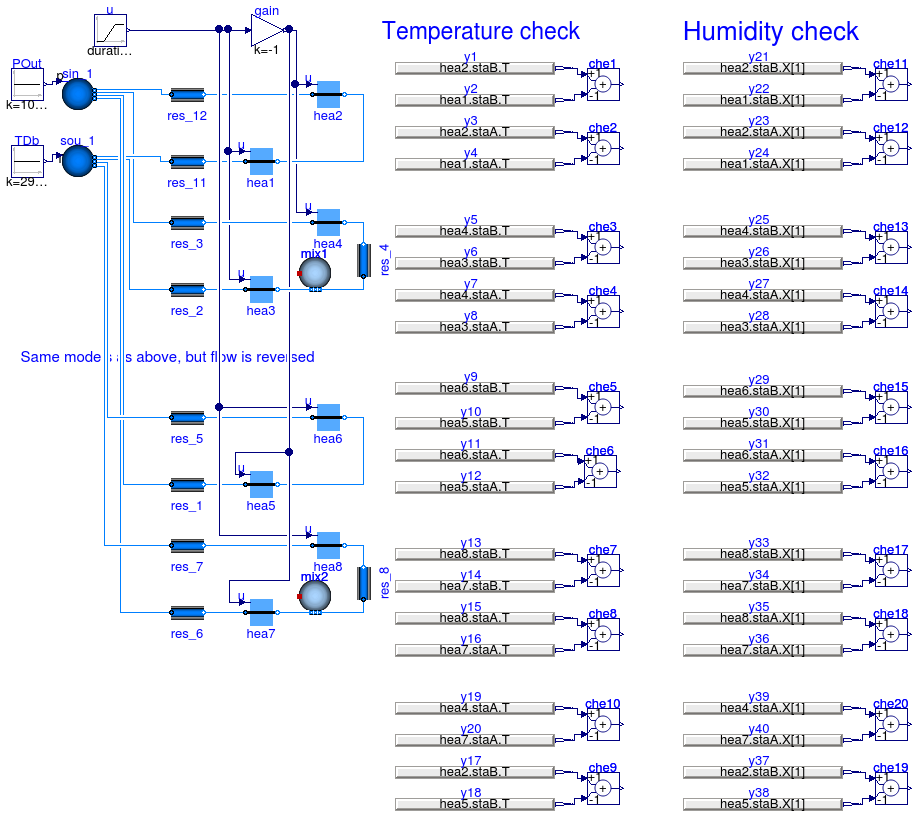

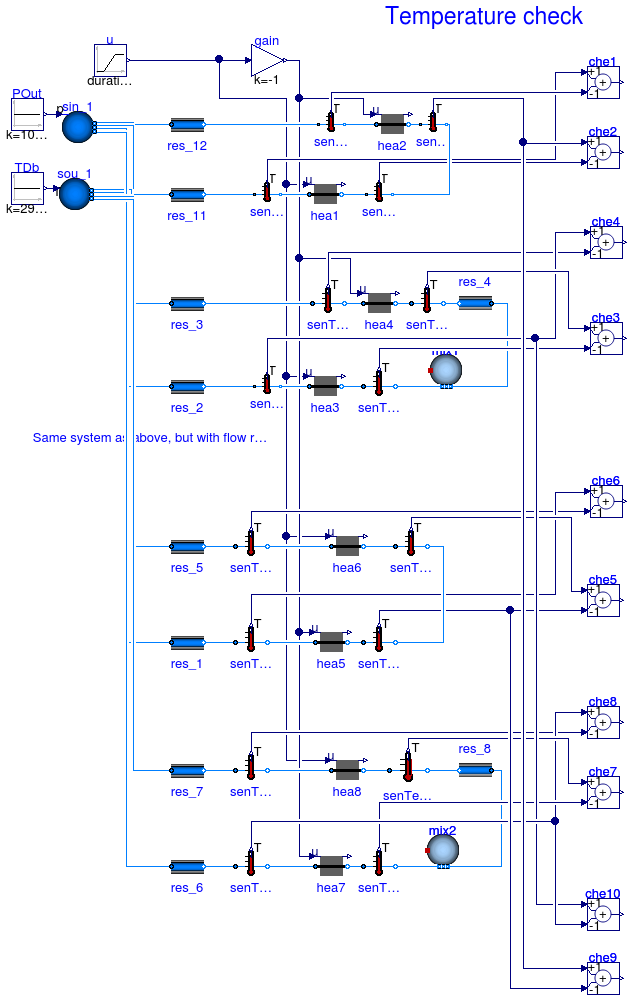

Model that tests a heat exchanger model with reverse flow

Information

Model that tests the basic class that is used for the heater models.

It adds and removes heat for forward and reverse flow.

The top and bottom models should give similar results,

although the sign of the temperature difference over the components

differ because of the reverse flow.

The model computes differences in results that are expected to be

close to each other after the initial transients decayed.

All temperature sensors are configured as steady-state sensors to avoid

differences in temperature due to the dynamic response of the sensor.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model HeaterCooler_u

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Water;

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea1(

redeclare package Medium = Medium,

Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Modelica.Blocks.Sources.Constant TDb(k=293.15) ;

Annex60.Fluid.Sources.Boundary_pT sou_1(

redeclare package Medium = Medium,

use_T_in=true,

nPorts=4,

p(displayUnit="Pa") = 101735,

T=293.15);

Annex60.Fluid.FixedResistances.PressureDrop res_11(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_12(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.Sources.Boundary_pT sin_1(

redeclare

package Medium = Medium,

use_p_in=true,

T=288.15,

nPorts=4);

Modelica.Blocks.Sources.Constant POut(k=101325);

Modelica.Blocks.Sources.Ramp u(

height=2,

duration=3600,

offset=-1,

startTime=0) ;

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea2(

redeclare package Medium = Medium,

Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Modelica.Blocks.Math.Gain gain(k=-1);

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea3(

redeclare package Medium = Medium,

Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_2(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_3(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea4(

redeclare package Medium = Medium, Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_4(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.MixingVolumes.MixingVolume mix1(

redeclare package Medium = Medium, V=

0.000001,

nPorts=2,

m_flow_nominal=0.5,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial);

Modelica.Blocks.Math.Add che1(k2=-1);

Modelica.Blocks.Math.Add che2(k2=-1);

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea5(

redeclare package Medium = Medium,

Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_1(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_5(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea6(

redeclare package Medium =

Medium, Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea7(

redeclare package Medium = Medium,

Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_6(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_7(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.HeatExchangers.HeaterCooler_u hea8(

redeclare package Medium = Medium, Q_flow_nominal=5000,

m_flow_nominal=0.5,

dp_nominal=200,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_8(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.MixingVolumes.MixingVolume mix2(

redeclare package Medium = Medium,

V=0.000001,

nPorts=2,

m_flow_nominal=0.5,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial);

Modelica.Blocks.Math.Add che9(k2=-1);

Modelica.Blocks.Math.Add che10(k2=-1);

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem2a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem2b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem1a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem1b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem3a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem3b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem4a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem4b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Modelica.Blocks.Math.Add che3(k2=-1);

Modelica.Blocks.Math.Add che4(k2=-1);

Modelica.Blocks.Math.Add che5(k2=-1);

Modelica.Blocks.Math.Add che6(k2=-1);

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem6b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem6a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem5b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem5a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Modelica.Blocks.Math.Add che7(k2=-1);

Modelica.Blocks.Math.Add che8(k2=-1);

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem8b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem8a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem7b(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

Annex60.Fluid.Sensors.TemperatureTwoPort

senTem7a(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

tau=0) ;

equation

connect(POut.y,sin_1. p_in);

connect(TDb.y,sou_1. T_in);

connect(u.y, hea1.u);

connect(gain.y, hea2.u);

connect(u.y, gain.u);

connect(u.y, hea3.u);

connect(gain.y, hea4.u);

connect(u.y, hea6.u);

connect(u.y, hea8.u);

connect(gain.y, hea5.u);

connect(gain.y, hea7.u);

connect(sin_1.ports[1], res_12.port_a);

connect(sin_1.ports[2], res_3.port_a);

connect(sou_1.ports[1], res_11.port_a);

connect(sou_1.ports[2], res_2.port_a);

connect(sin_1.ports[3], res_1.port_a);

connect(sin_1.ports[4], res_6.port_a);

connect(sou_1.ports[3], res_5.port_a);

connect(sou_1.ports[4], res_7.port_a);

connect(mix1.ports[1], res_4.port_a);

connect(mix2.ports[1], res_8.port_a);

connect(senTem1a.T,che1. u1);

connect(senTem2a.T,che1. u2);

connect(senTem1b.T,che2. u2);

connect(senTem2b.T,che2. u1);

connect(senTem4a.T,che4. u2);

connect(senTem3a.T,che4. u1);

connect(senTem4b.T,che3. u1);

connect(senTem3b.T,che3. u2);

connect(senTem6a.T,che6. u2);

connect(senTem5a.T,che6. u1);

connect(senTem6b.T,che5. u1);

connect(senTem5b.T,che5. u2);

connect(senTem8a.T,che8. u2);

connect(senTem7a.T,che8. u1);

connect(senTem8b.T,che7. u1);

connect(senTem7b.T,che7. u2);

connect(senTem3a.T,che10. u1);

connect(senTem7a.T,che10. u2);

connect(senTem2b.T,che9. u1);

connect(senTem5b.T,che9. u2);

connect(res_12.port_b, senTem2a.port_a);

connect(senTem2a.port_b, hea2.port_a);

connect(hea2.port_b, senTem2b.port_a);

connect(senTem2b.port_b, senTem1b.port_b);

connect(hea1.port_b, senTem1b.port_a);

connect(res_11.port_b, senTem1a.port_a);

connect(senTem1a.port_b, hea1.port_a);

connect(res_2.port_b, senTem3a.port_a);

connect(senTem3a.port_b, hea3.port_a);

connect(hea3.port_b, senTem3b.port_a);

connect(senTem3b.port_b, mix1.ports[2]);

connect(hea4.port_b, senTem4b.port_a);

connect(res_3.port_b, senTem4a.port_a);

connect(senTem4a.port_b, hea4.port_a);

connect(senTem4b.port_b, res_4.port_b);

connect(res_5.port_b, senTem6a.port_a);

connect(senTem6a.port_b, hea6.port_a);

connect(hea6.port_b, senTem6b.port_a);

connect(senTem6b.port_b, senTem5b.port_b);

connect(senTem5b.port_a, hea5.port_b);

connect(hea5.port_a, senTem5a.port_b);

connect(senTem5a.port_a, res_1.port_b);

connect(res_7.port_b, senTem8a.port_a);

connect(senTem8a.port_b, hea8.port_a);

connect(hea8.port_b, senTem8b.port_a);

connect(senTem8b.port_b, res_8.port_b);

connect(mix2.ports[2], senTem7b.port_b);

connect(senTem7b.port_a, hea7.port_b);

connect(hea7.port_a, senTem7a.port_b);

connect(senTem7a.port_a, res_6.port_b);

end HeaterCooler_u;

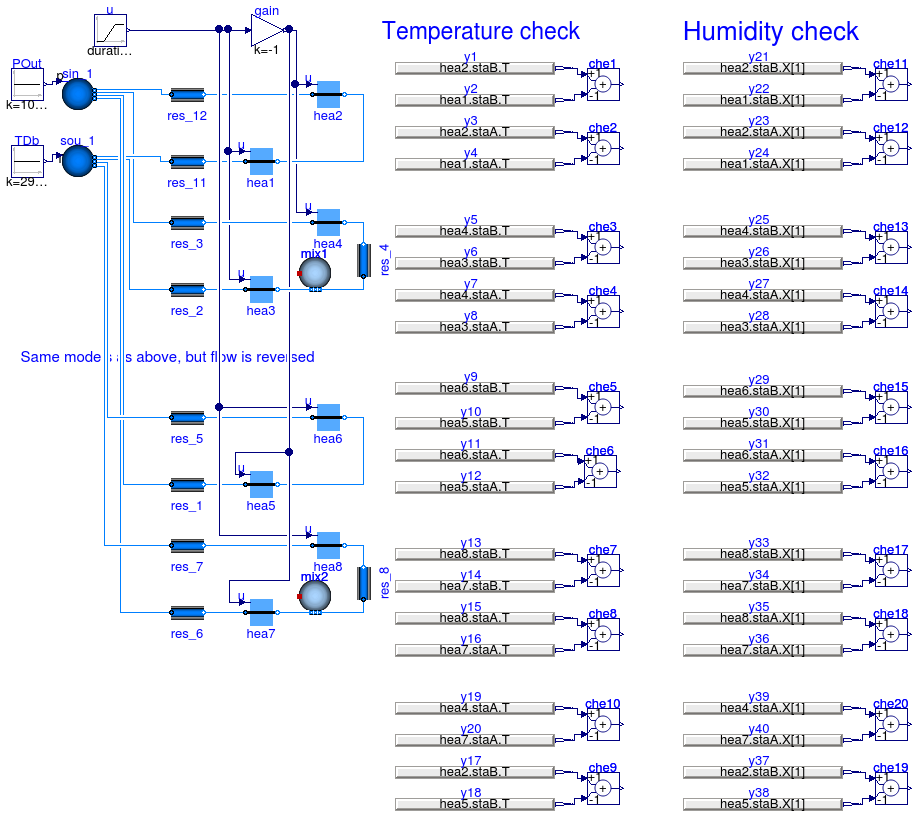

Information

Model that tests the basic class that is used for the humidifier model.

It adds and removes water for forward and reverse flow.

The top and bottom models should give similar results, although

the sign of the humidity difference over the components differ

because of the reverse flow.

The model computes differences of results that

are expected to be close to each other after the

initial transients decayed.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | mWat_flow_nominal | 0.001 | Nominal water mass flow rate [kg/s] |

Modelica definition

model Humidifier_u

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

parameter Modelica.SIunits.MassFlowRate mWat_flow_nominal = 0.001

;

Humidifier hea1(

redeclare package Medium =

Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Modelica.Blocks.Sources.Constant TDb(k=293.15) ;

Annex60.Fluid.Sources.Boundary_pT sou_1(

redeclare package Medium = Medium,

use_T_in=true,

nPorts=4,

p(displayUnit="Pa") = 101435,

T=293.15);

Annex60.Fluid.FixedResistances.PressureDrop res_11(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_12(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.Sources.Boundary_pT sin_1(

redeclare package Medium = Medium,

use_p_in=true,

T=288.15,

nPorts=4);

Modelica.Blocks.Sources.Constant POut(k=101325);

Modelica.Blocks.Sources.Ramp u(

duration=3600,

startTime=0,

height=1,

offset=0) ;

Humidifier hea2(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Modelica.Blocks.Math.Gain gain(k=-1);

Humidifier hea3(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_2(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_3(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Humidifier hea4(

redeclare package Medium = Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_4(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.MixingVolumes.MixingVolume mix1(

redeclare package Medium = Medium,

V=0.000001,

nPorts=2,

m_flow_nominal=0.5,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial);

Modelica.Blocks.Math.Add che1(k2=-1);

Modelica.Blocks.Sources.RealExpression y1(y=hea2.staB.T);

Modelica.Blocks.Sources.RealExpression y2(y=hea1.staB.T);

Modelica.Blocks.Math.Add che2(k2=-1);

Modelica.Blocks.Sources.RealExpression y3(y=hea2.staA.T);

Modelica.Blocks.Sources.RealExpression y4(y=hea1.staA.T);

Modelica.Blocks.Math.Add che3(k2=-1);

Modelica.Blocks.Sources.RealExpression y5(y=hea4.staB.T);

Modelica.Blocks.Sources.RealExpression y6(y=hea3.staB.T);

Modelica.Blocks.Math.Add che4(k2=-1);

Modelica.Blocks.Sources.RealExpression y7(y=hea4.staA.T);

Modelica.Blocks.Sources.RealExpression y8(y=hea3.staA.T);

Humidifier hea5(

redeclare package Medium =

Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_1(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_5(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Humidifier hea6(

redeclare package Medium =

Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Humidifier hea7(

redeclare package Medium =

Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

massDynamics=Modelica.Fluid.Types.Dynamics.DynamicFreeInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_6(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.FixedResistances.PressureDrop res_7(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Humidifier hea8(

redeclare package Medium =

Medium,

m_flow_nominal=0.5,

mWat_flow_nominal=mWat_flow_nominal,

dp_nominal=50,

show_T=true,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial)

;

Annex60.Fluid.FixedResistances.PressureDrop res_8(

redeclare package Medium = Medium,

dp_nominal=5,

m_flow_nominal=0.5);

Annex60.Fluid.MixingVolumes.MixingVolume mix2(

redeclare package Medium = Medium, V=

0.000001,

nPorts=2,

m_flow_nominal=0.5,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial);

Modelica.Blocks.Math.Add che5(k2=-1);

Modelica.Blocks.Sources.RealExpression y9(y=hea6.staB.T);

Modelica.Blocks.Sources.RealExpression y10(

y=hea5.staB.T);

Modelica.Blocks.Math.Add che6(k2=-1);

Modelica.Blocks.Sources.RealExpression y11(

y=hea6.staA.T);

Modelica.Blocks.Sources.RealExpression y12(

y=hea5.staA.T);

Modelica.Blocks.Math.Add che7(k2=-1);

Modelica.Blocks.Sources.RealExpression y13(

y=hea8.staB.T);

Modelica.Blocks.Sources.RealExpression y14(

y=hea7.staB.T);

Modelica.Blocks.Math.Add che8(k2=-1);

Modelica.Blocks.Sources.RealExpression y15(

y=hea8.staA.T);

Modelica.Blocks.Sources.RealExpression y16(

y=hea7.staA.T);

Modelica.Blocks.Math.Add che9(k2=-1);

Modelica.Blocks.Sources.RealExpression y17(y=hea2.staB.T);

Modelica.Blocks.Sources.RealExpression y18(y=hea5.staB.T);

Modelica.Blocks.Math.Add che10(k2=-1);

Modelica.Blocks.Sources.RealExpression y19(y=hea4.staA.T);

Modelica.Blocks.Sources.RealExpression y20(y=hea7.staA.T);

Modelica.Blocks.Math.Add che11(k2=-1);

Modelica.Blocks.Sources.RealExpression y21(y=hea2.staB.X[1]);

Modelica.Blocks.Sources.RealExpression y22(y=hea1.staB.X[1]);

Modelica.Blocks.Math.Add che12(k2=-1);

Modelica.Blocks.Sources.RealExpression y23(

y=hea2.staA.X[1]);

Modelica.Blocks.Sources.RealExpression y24(

y=hea1.staA.X[1]);

Modelica.Blocks.Math.Add che13(k2=-1);

Modelica.Blocks.Sources.RealExpression y25(

y=hea4.staB.X[1]);

Modelica.Blocks.Sources.RealExpression y26(

y=hea3.staB.X[1]);

Modelica.Blocks.Math.Add che14(k2=-1);

Modelica.Blocks.Sources.RealExpression y27(

y=hea4.staA.X[1]);

Modelica.Blocks.Sources.RealExpression y28(

y=hea3.staA.X[1]);

Modelica.Blocks.Math.Add che15(k2=-1);

Modelica.Blocks.Sources.RealExpression y29(

y=hea6.staB.X[1]);

Modelica.Blocks.Sources.RealExpression y30(

y=hea5.staB.X[1]);

Modelica.Blocks.Math.Add che16(k2=-1);

Modelica.Blocks.Sources.RealExpression y31(

y=hea6.staA.X[1]);

Modelica.Blocks.Sources.RealExpression y32(

y=hea5.staA.X[1]);

Modelica.Blocks.Math.Add che17(k2=-1);

Modelica.Blocks.Sources.RealExpression y33(

y=hea8.staB.X[1]);

Modelica.Blocks.Sources.RealExpression y34(

y=hea7.staB.X[1]);

Modelica.Blocks.Math.Add che18(k2=-1);

Modelica.Blocks.Sources.RealExpression y35(

y=hea8.staA.X[1]);

Modelica.Blocks.Sources.RealExpression y36(

y=hea7.staA.X[1]);

Modelica.Blocks.Math.Add che19(k2=-1);

Modelica.Blocks.Sources.RealExpression y37(y=hea2.staB.X[1]);

Modelica.Blocks.Sources.RealExpression y38(y=hea5.staB.X[1]);

Modelica.Blocks.Math.Add che20(k2=-1);

Modelica.Blocks.Sources.RealExpression y39(y=hea4.staA.X[1]);

Modelica.Blocks.Sources.RealExpression y40(y=hea7.staA.X[1]);

protected

model Humidifier

extends Annex60.Fluid.MassExchangers.Humidifier_u;

Medium.ThermodynamicState staA=

Medium.setState_phX(port_a.p,

actualStream(port_a.h_outflow),

actualStream(port_a.Xi_outflow))

;

Medium.ThermodynamicState staB=

Medium.setState_phX(port_b.p,

actualStream(port_b.h_outflow),

actualStream(port_b.Xi_outflow))

;

end Humidifier;

equation

connect(POut.y,sin_1. p_in);

connect(TDb.y,sou_1. T_in);

connect(res_11.port_b, hea1.port_a);

connect(u.y, hea1.u);

connect(gain.y, hea2.u);

connect(u.y, gain.u);

connect(res_12.port_b, hea2.port_a);

connect(res_2.port_b, hea3.port_a);

connect(u.y, hea3.u);

connect(gain.y, hea4.u);

connect(res_3.port_b, hea4.port_a);

connect(hea4.port_b, res_4.port_b);

connect(hea1.port_b, hea2.port_b);

connect(y1.y,che1. u1);

connect(y2.y,che1. u2);

connect(y3.y,che2. u1);

connect(y4.y,che2. u2);

connect(y5.y,che3. u1);

connect(y6.y,che3. u2);

connect(y7.y,che4. u1);

connect(y8.y,che4. u2);

connect(res_1.port_b, hea5.port_a);

connect(res_5.port_b, hea6.port_a);

connect(res_6.port_b,hea7. port_a);

connect(res_7.port_b,hea8. port_a);

connect(hea8.port_b,res_8. port_b);

connect(hea5.port_b,hea6. port_b);

connect(y9.y,che5. u1);

connect(y10.y,che5. u2);

connect(y11.y,che6. u1);

connect(y12.y,che6. u2);

connect(y13.y,che7. u1);

connect(y14.y,che7. u2);

connect(y15.y,che8. u1);

connect(y16.y,che8. u2);

connect(y17.y,che9. u1);

connect(y18.y,che9. u2);

connect(y19.y,che10. u1);

connect(y20.y,che10. u2);

connect(u.y, hea6.u);

connect(u.y, hea8.u);

connect(gain.y, hea5.u);

connect(gain.y, hea7.u);

connect(y21.y,che11. u1);

connect(y22.y,che11. u2);

connect(y23.y,che12. u1);

connect(y24.y,che12. u2);

connect(y25.y,che13. u1);

connect(y26.y,che13. u2);

connect(y27.y,che14. u1);

connect(y28.y,che14. u2);

connect(y29.y,che15. u1);

connect(y30.y,che15. u2);

connect(y31.y,che16. u1);

connect(y32.y,che16. u2);

connect(y33.y,che17. u1);

connect(y34.y,che17. u2);

connect(y35.y,che18. u1);

connect(y36.y,che18. u2);

connect(y37.y,che19. u1);

connect(y38.y,che19. u2);

connect(y39.y,che20. u1);

connect(y40.y,che20. u2);

connect(sin_1.ports[1], res_12.port_a);

connect(sin_1.ports[2], res_3.port_a);

connect(sou_1.ports[1], res_11.port_a);

connect(sou_1.ports[2], res_2.port_a);

connect(sin_1.ports[3], res_1.port_a);

connect(sin_1.ports[4], res_6.port_a);

connect(sou_1.ports[3], res_5.port_a);

connect(sou_1.ports[4], res_7.port_a);

connect(hea3.port_b, mix1.ports[1]);

connect(mix1.ports[2], res_4.port_a);

connect(hea7.port_b, mix2.ports[1]);

connect(mix2.ports[2], res_8.port_a);

end Humidifier_u;

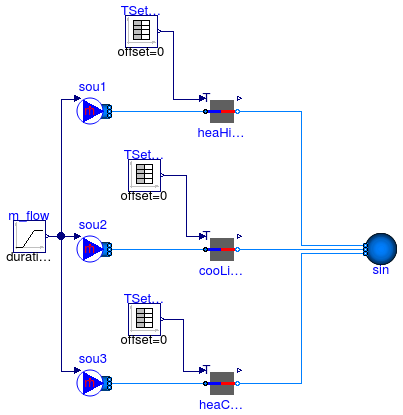

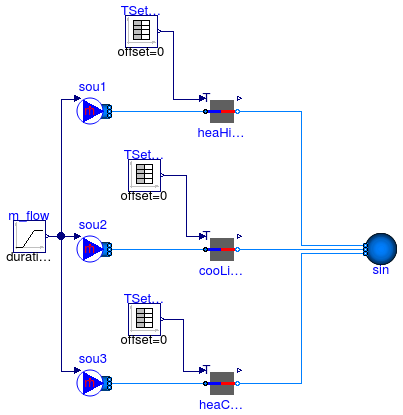

Test model for prescribed outlet state

Information

Model that demonstrates the use of an ideal heater and an ideal cooler.

The heater model has an almost unlimited positive capacity (Q_flow_nominal = 1.0e10 Watts),

and hence its outlet temperature always reaches the set point temperatures.

The cooler model has a limited negative capacitiy (Q_flow_nominal = 1000 Watts), and hence

its outlet temperature reaches only a limited value corresponding to its

maximum negative capacity.

There is also a heater and cooler with unlimited capacity.

At t=1000 second, the flow reverses its direction.

Each flow leg has the same mass flow rate. There are three mass flow sources

as using one source only would yield a nonlinear system of equations that

needs to be solved to determine the mass flow rate distribution.

The heater and cooler models have the parameter show_T set to true

to allow inspecting the temperatures at their ports.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Parameters

| Type | Name | Default | Description |

|---|

| MassFlowRate | m_flow_nominal | 0.1 | Nominal mass flow rate [kg/s] |

Modelica definition

model PrescribedOutletState

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Water;

parameter Modelica.SIunits.MassFlowRate m_flow_nominal=0.1

;

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium = Medium,

use_T_in=false,

p(displayUnit="Pa"),

T=293.15,

nPorts=3) ;

Annex60.Fluid.Interfaces.PrescribedOutletState heaHigPow(

redeclare package Medium = Medium,

Q_flow_maxHeat=1.0e10,

m_flow_small=1E-4*

abs(m_flow_nominal),

show_T=true,

m_flow_nominal=m_flow_nominal)

;

Modelica.Blocks.Sources.TimeTable TSetHeat(table=[0,273.15 + 20.0; 120,273.15

+ 20.0; 120,273.15 + 60.0; 500,273.15 + 60.0; 500,273.15 + 30.0; 1200,273.15 + 30.0])

;

Annex60.Fluid.Interfaces.PrescribedOutletState cooLimPow(

redeclare package Medium = Medium,

Q_flow_maxCool=-1000,

m_flow_small=1E-4*

abs(m_flow_nominal),

show_T=true,

m_flow_nominal=m_flow_nominal)

;

Modelica.Blocks.Sources.TimeTable TSetCool(table=[0,273.15 + 20.0; 120,273.15

+ 20.0; 120,273.15 + 15.0; 500,273.15 + 15.0; 500,273.15 + 10.0; 1200,273.15 + 10.0])

;

Annex60.Fluid.Interfaces.PrescribedOutletState heaCooUnl(

redeclare package Medium = Medium,

m_flow_small=1E-4*

abs(m_flow_nominal),

show_T=true,

m_flow_nominal=m_flow_nominal)

;

Modelica.Blocks.Sources.TimeTable TSetCoolHeat(table=[0,273.15 + 20.0; 120,273.15

+ 20.0; 120,273.15 + 15.0; 500,273.15 + 15.0; 500,273.15 + 30.0; 1200,273.15

+ 30.0]) ;

Modelica.Blocks.Sources.Ramp m_flow(

height=-2*m_flow_nominal,

duration=100,

offset=m_flow_nominal,

startTime=1000) ;

Annex60.Fluid.Sources.MassFlowSource_T sou1(

redeclare package Medium = Medium,

use_m_flow_in=true,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T sou2(

redeclare package Medium = Medium,

use_m_flow_in=true,

T=293.15,

nPorts=1) ;

Annex60.Fluid.Sources.MassFlowSource_T sou3(

redeclare package Medium = Medium,

use_m_flow_in=true,

T=293.15,

nPorts=1) ;

equation

connect(TSetHeat.y,heaHigPow. TSet);

connect(TSetCool.y,cooLimPow. TSet);

connect(TSetCoolHeat.y,heaCooUnl. TSet);

connect(m_flow.y, sou1.m_flow_in);

connect(m_flow.y, sou2.m_flow_in);

connect(m_flow.y, sou3.m_flow_in);

connect(sou1.ports[1], heaHigPow.port_a);

connect(sou2.ports[1], cooLimPow.port_a);

connect(sou3.ports[1], heaCooUnl.port_a);

connect(heaCooUnl.port_b, sin.ports[1]);

connect(cooLimPow.port_b, sin.ports[2]);

connect(heaHigPow.port_b, sin.ports[3]);

end PrescribedOutletState;

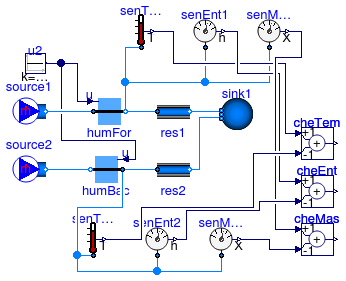

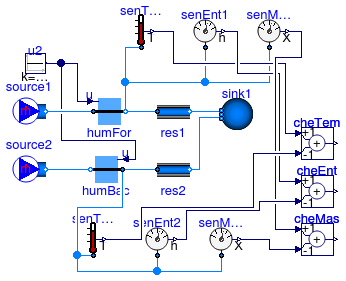

Model that tests the reverse flow for a humidifier

Information

This model tests whether the results for a humidifer are

identical for forward flow and reverse flow.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model ReverseFlowHumidifier

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

Modelica.Blocks.Math.Add cheTem(k2=-1)

;

Modelica.Blocks.Math.Add cheEnt(k2=-1)

;

Modelica.Blocks.Math.Add cheMas(k2=-1)

;

Annex60.Fluid.MassExchangers.Humidifier_u humBac(

redeclare package Medium = Medium,

dp_nominal=0,

m_flow(start=1),

m_flow_nominal=1,

mWat_flow_nominal=0.1,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

T=283.15) ;

Annex60.Fluid.MassExchangers.Humidifier_u humFor(

redeclare package Medium = Medium,

dp_nominal=0,

m_flow(start=1),

m_flow_nominal=1,

mWat_flow_nominal=0.1,

energyDynamics=Modelica.Fluid.Types.Dynamics.FixedInitial,

T=283.15) ;

Modelica.Blocks.Sources.Constant u2(k=0.01) ;

Modelica.Fluid.Sources.MassFlowSource_T source1(

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

T(displayUnit="K") = 323.15,

X={0.01,0.99},

nPorts=1,

m_flow=0.5) ;

Annex60.Fluid.Sources.FixedBoundary sink1(

redeclare package Medium = Medium,

nPorts=2) ;

Sensors.SpecificEnthalpy senEnt1(

redeclare package Medium = Medium)

;

Sensors.Temperature senTem1(

redeclare package Medium = Medium)

;

Sensors.MassFraction senMas1(

redeclare package Medium = Medium)

;

Sensors.Temperature senTem2(

redeclare package Medium = Medium)

;

Sensors.SpecificEnthalpy senEnt2(

redeclare package Medium = Medium)

;

Sensors.MassFraction senMas2(

redeclare package Medium = Medium)

;

FixedResistances.PressureDrop res1(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

FixedResistances.PressureDrop res2(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

Modelica.Fluid.Sources.MassFlowSource_T source2(

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

T(displayUnit="K") = 323.15,

X={0.01,0.99},

nPorts=1,

m_flow=0.5) ;

equation

connect(u2.y, humFor.u);

connect(u2.y, humBac.u);

connect(humFor.port_b, senTem1.port);

connect(humFor.port_b, senEnt1.port);

connect(humFor.port_b, senMas1.port);

connect(humBac.port_a, senTem2.port);

connect(humBac.port_a, senEnt2.port);

connect(humBac.port_a, senMas2.port);

connect(humFor.port_b, res1.port_a);

connect(res1.port_b, sink1.ports[1]);

connect(humBac.port_a, res2.port_a);

connect(res2.port_b, sink1.ports[2]);

connect(senTem1.T,cheTem. u1);

connect(senEnt1.h_out,cheEnt. u1);

connect(senMas1.X,cheMas. u1);

connect(senTem2.T,cheTem. u2);

connect(senEnt2.h_out,cheEnt. u2);

connect(senMas2.X,cheMas. u2);

connect(humFor.port_a, source1.ports[1]);

connect(source2.ports[1], humBac.port_b);

end ReverseFlowHumidifier;

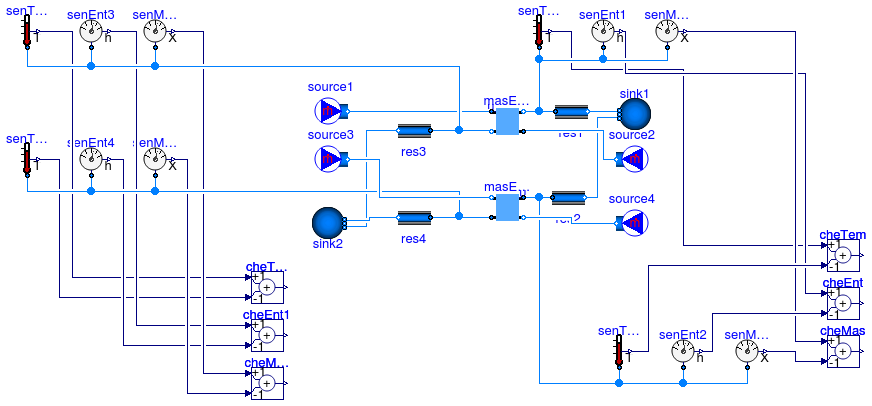

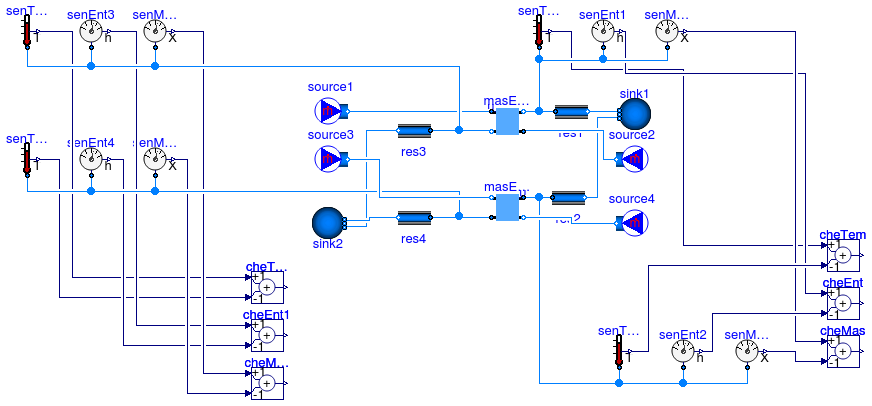

Model that tests the reverse flow for a mass exchanger

Information

This model tests whether the results for a mass exchanger are

identical for forward flow and reverse flow.

Note that if the latent heat transfer effectiveness is non-zero, then

the results will differ. The reason is that the maximum capacity stream

is computed using the mass flow rates at port_a1

and port_a2. For reverse flow, they are not equal if

moisture is added to the mass flow rate. Using an average mass flow rate

in computing the heat and moisture transfer would lead to identical results,

but it would introduce additional nonlinear equations that need to be solved.

Therefore, the model uses the mass flow rates at port_a1

and port_a2.

Note: This problem fails to translate in Dymola 2012 due to an error in Dymola's support

of stream connector. This bug will be corrected in future versions of Dymola.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model ReverseFlowMassExchanger

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

Modelica.Blocks.Math.Add cheTem(k2=-1)

;

Modelica.Blocks.Math.Add cheEnt(k2=-1)

;

Modelica.Blocks.Math.Add cheMas(k2=-1)

;

Modelica.Fluid.Sources.MassFlowSource_T source2(

m_flow=1,

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

nPorts=1,

T(displayUnit="degC") = 303.15,

X={0.02,0.98});

Annex60.Fluid.MassExchangers.ConstantEffectiveness masExcFor(

redeclare package Medium1 = Medium,

redeclare package Medium2 = Medium,

m1_flow_nominal=1,

m2_flow_nominal=1,

dp1_nominal=0,

dp2_nominal=0,

epsL=0) ;

Annex60.Fluid.MassExchangers.ConstantEffectiveness masExcRev(

redeclare package Medium1 = Medium,

redeclare package Medium2 = Medium,

m1_flow_nominal=1,

m2_flow_nominal=1,

dp1_nominal=0,

dp2_nominal=0,

epsL=0) ;

Annex60.Fluid.Sources.FixedBoundary sink2(

redeclare package Medium = Medium,

nPorts=2) ;

FixedResistances.PressureDrop res3(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

FixedResistances.PressureDrop res4(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

Sensors.SpecificEnthalpy senEnt3(

redeclare package Medium = Medium);

Sensors.Temperature senTem3(

redeclare package Medium = Medium);

Sensors.MassFraction senMas3(

redeclare package Medium = Medium);

Sensors.SpecificEnthalpy senEnt4(

redeclare package Medium = Medium);

Sensors.Temperature senTem4(

redeclare package Medium = Medium);

Sensors.MassFraction senMas4(

redeclare package Medium = Medium);

Modelica.Blocks.Math.Add cheTem1(k2=-1)

;

Modelica.Blocks.Math.Add cheEnt1(k2=-1)

;

Modelica.Blocks.Math.Add cheMas1(k2=-1)

;

Modelica.Fluid.Sources.MassFlowSource_T source3(

m_flow=1,

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

X={0.01,0.99},

nPorts=1,

T(displayUnit="degC") = 293.15);

Modelica.Fluid.Sources.MassFlowSource_T source4(

m_flow=1,

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

nPorts=1,

T(displayUnit="degC") = 303.15,

X={0.02,0.98});

Modelica.Fluid.Sources.MassFlowSource_T source1(

m_flow=1,

redeclare package Medium = Medium,

use_m_flow_in=false,

use_T_in=false,

use_X_in=false,

X={0.01,0.99},

nPorts=1,

T(displayUnit="degC") = 293.15);

Annex60.Fluid.Sources.FixedBoundary sink1(

redeclare package Medium = Medium,

nPorts=2) ;

Sensors.SpecificEnthalpy senEnt1(

redeclare package Medium = Medium);

Sensors.Temperature senTem1(

redeclare package Medium = Medium);

Sensors.MassFraction senMas1(

redeclare package Medium = Medium);

Sensors.Temperature senTem2(

redeclare package Medium = Medium);

Sensors.SpecificEnthalpy senEnt2(

redeclare package Medium = Medium);

Sensors.MassFraction senMas2(

redeclare package Medium = Medium);

FixedResistances.PressureDrop res1(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

FixedResistances.PressureDrop res2(

redeclare package Medium = Medium,

m_flow_nominal=1,

from_dp=true,

linearized=false,

dp_nominal=1000) ;

equation

connect(res1.port_b, sink1.ports[1]);

connect(res2.port_b, sink1.ports[2]);

connect(senTem1.T,cheTem. u1);

connect(senEnt1.h_out,cheEnt. u1);

connect(senMas1.X,cheMas. u1);

connect(senTem2.T,cheTem. u2);

connect(senEnt2.h_out,cheEnt. u2);

connect(senMas2.X,cheMas. u2);

connect(masExcFor.port_b1, res1.port_a);

connect(masExcFor.port_a1, source1.ports[1]);

connect(masExcRev.port_a1, res2.port_a);

connect(source2.ports[1], masExcFor.port_a2);

connect(masExcRev.port_a1, senTem2.port);

connect(masExcRev.port_a1, senEnt2.port);

connect(masExcRev.port_a1, senMas2.port);

connect(masExcFor.port_b1, senTem1.port);

connect(masExcFor.port_b1, senEnt1.port);

connect(masExcFor.port_b1, senMas1.port);

connect(masExcFor.port_b2, res3.port_a);

connect(masExcRev.port_a2, res4.port_a);

connect(res3.port_b, sink2.ports[1]);

connect(res4.port_b, sink2.ports[2]);

connect(senTem3.T,cheTem1. u1);

connect(senTem4.T,cheTem1. u2);

connect(senEnt3.h_out,cheEnt1. u1);

connect(senEnt4.h_out,cheEnt1. u2);

connect(senMas3.X,cheMas1. u1);

connect(senMas4.X,cheMas1. u2);

connect(masExcFor.port_b2, senTem3.port);

connect(masExcFor.port_b2, senEnt3.port);

connect(masExcFor.port_b2, senMas3.port);

connect(masExcRev.port_a2, senTem4.port);

connect(masExcRev.port_a2, senEnt4.port);

connect(masExcRev.port_a2, senMas4.port);

connect(source3.ports[1], masExcRev.port_b1);

connect(source4.ports[1], masExcRev.port_b2);

end ReverseFlowMassExchanger;

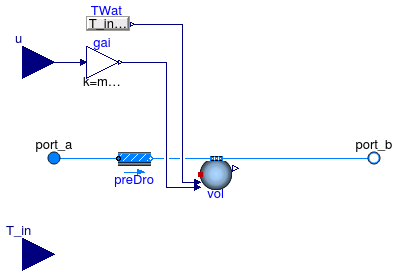

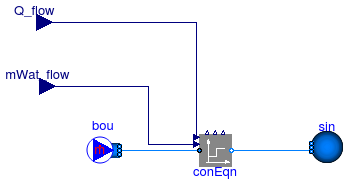

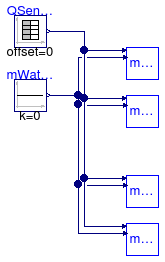

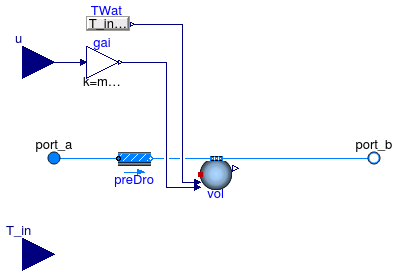

Model that tests the static two port conservation equation

Information

Model that tests the conservation equations that are used

for the heat and mass balance.

The instances have either water or air, and either allow or prohibit

flow reversal.

This example tests the implementation of the steady-state balance.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model StaticTwoPortConservationEquation

extends Modelica.Icons.Example;

package MediumW =

Annex60.Media.Water ;

package MediumA =

Annex60.Media.Air ;

Modelica.Blocks.Sources.Constant mWat_flow(k=0)

;

Modelica.Blocks.Sources.TimeTable QSen_flow(startTime=0, table=[

0,-100;

900,-100;

900,0;

1800,0;

1800,100])

;

SubModel modWatRev(

redeclare package Medium = MediumW,

allowFlowReversal=true,

use_mWat_flow = false) ;

SubModel modWatNoRev(

redeclare package Medium = MediumW,

allowFlowReversal=false,

use_mWat_flow = false) ;

SubModel modAirRev(

redeclare package Medium = MediumA,

allowFlowReversal=true,

use_mWat_flow = true) ;

SubModel modAirNoRev(

redeclare package Medium = MediumA,

allowFlowReversal=false,

use_mWat_flow = true) ;

equation

connect(QSen_flow.y, modWatRev.Q_flow);

connect(mWat_flow.y, modWatRev.mWat_flow);

protected

model SubModel

replaceable package Medium =

Modelica.Media.Interfaces.PartialMedium

;

Sources.MassFlowSource_T bou(

nPorts=1,

redeclare package Medium =

Medium,

m_flow=0.01) ;

Annex60.Fluid.Interfaces.StaticTwoPortConservationEquation conEqn(

redeclare package Medium =

Medium,

m_flow_nominal=0.01,

show_T=true,

allowFlowReversal=allowFlowReversal,

use_mWat_flow=use_mWat_flow,

prescribedHeatFlowRate=true) ;

Annex60.Fluid.Sources.Boundary_pT sin(

use_p_in=false,

redeclare package Medium =

Medium,

nPorts=1,

p=101325,

T=283.15) ;

Modelica.Blocks.Interfaces.RealInput Q_flow(unit="W");

Modelica.Blocks.Interfaces.RealInput mWat_flow(unit="kg/s");

parameter Boolean use_mWat_flow

;

parameter Boolean allowFlowReversal=true

;

equation

connect(conEqn.port_b, sin.ports[1]);

connect(conEqn.port_a, bou.ports[1]);

connect(Q_flow, conEqn.Q_flow);

connect(mWat_flow, conEqn.mWat_flow);

end SubModel;

equation

connect(QSen_flow.y, modWatNoRev.Q_flow);

connect(mWat_flow.y, modWatNoRev.mWat_flow);

connect(QSen_flow.y, modAirRev.Q_flow);

connect(mWat_flow.y, modAirRev.mWat_flow);

connect(QSen_flow.y, modAirNoRev.Q_flow);

connect(mWat_flow.y, modAirNoRev.mWat_flow);

end StaticTwoPortConservationEquation;

Model for humidifier that adds a variable for the thermodynamic states at its ports

Information

Extends from Annex60.Fluid.MassExchangers.Humidifier_u (Ideal humidifier or dehumidifier with prescribed water mass flow rate addition or subtraction).

Parameters

| Type | Name | Default | Description |

|---|

| replaceable package Medium | PartialCondensingGases | Medium in the component |

| Boolean | use_T_in | false | Get the temperature from the input connector |

| Temperature | T | 293.15 | Temperature of water that is added to the fluid stream (used if use_T_in=false) [K] |

| MassFlowRate | mWat_flow_nominal | | Water mass flow rate at u=1, positive for humidification [kg/s] |

| Nominal condition |

| MassFlowRate | m_flow_nominal | | Nominal mass flow rate [kg/s] |

| PressureDifference | dp_nominal | | Pressure difference [Pa] |

| Assumptions |

| Boolean | allowFlowReversal | true | = false to simplify equations, assuming, but not enforcing, no flow reversal |

| Advanced |

| MassFlowRate | m_flow_small | 1E-4*abs(m_flow_nominal) | Small mass flow rate for regularization of zero flow [kg/s] |

| Boolean | homotopyInitialization | true | = true, use homotopy method |

| Diagnostics |

| Boolean | show_T | false | = true, if actual temperature at port is computed |

| Flow resistance |

| Boolean | from_dp | false | = true, use m_flow = f(dp) else dp = f(m_flow) |

| Boolean | linearizeFlowResistance | false | = true, use linear relation between m_flow and dp for any flow rate |

| Real | deltaM | 0.1 | Fraction of nominal flow rate where flow transitions to laminar |

| Dynamics |

| Nominal condition |

| Time | tau | 30 | Time constant at nominal flow (if energyDynamics <> SteadyState) [s] |

| Equations |

| Dynamics | energyDynamics | Modelica.Fluid.Types.Dynamic... | Type of energy balance: dynamic (3 initialization options) or steady state |

| Dynamics | massDynamics | energyDynamics | Type of mass balance: dynamic (3 initialization options) or steady state |

| Initialization |

| AbsolutePressure | p_start | Medium.p_default | Start value of pressure [Pa] |

| Temperature | T_start | Medium.T_default | Start value of temperature [K] |

| MassFraction | X_start[Medium.nX] | Medium.X_default | Start value of mass fractions m_i/m [kg/kg] |

| ExtraProperty | C_start[Medium.nC] | fill(0, Medium.nC) | Start value of trace substances |

Connectors

| Type | Name | Description |

|---|

| FluidPort_a | port_a | Fluid connector a (positive design flow direction is from port_a to port_b) |

| FluidPort_b | port_b | Fluid connector b (positive design flow direction is from port_a to port_b) |

| input RealInput | T_in | Temperature of water added to the fluid stream |

| input RealInput | u | Control input |

Modelica definition

Parameters

| Type | Name | Default | Description |

|---|

| replaceable package Medium | Modelica.Media.Interfaces.Pa... | Medium model |

| Boolean | use_mWat_flow | | Set to true to enable exchange of moisture |

| Boolean | allowFlowReversal | true | = false to simplify equations, assuming, but not enforcing, no flow reversal |

Connectors

| Type | Name | Description |

|---|

| replaceable package Medium | Medium model |

| input RealInput | Q_flow | [W] |

| input RealInput | mWat_flow | [kg/s] |

Modelica definition

model SubModel

replaceable package Medium =

Modelica.Media.Interfaces.PartialMedium

;

Sources.MassFlowSource_T bou(

nPorts=1,

redeclare package Medium =

Medium,

m_flow=0.01) ;

Annex60.Fluid.Interfaces.StaticTwoPortConservationEquation conEqn(

redeclare package Medium =

Medium,

m_flow_nominal=0.01,

show_T=true,

allowFlowReversal=allowFlowReversal,

use_mWat_flow=use_mWat_flow,

prescribedHeatFlowRate=true) ;

Annex60.Fluid.Sources.Boundary_pT sin(

use_p_in=false,

redeclare package Medium =

Medium,

nPorts=1,

p=101325,

T=283.15) ;

Modelica.Blocks.Interfaces.RealInput Q_flow(unit="W");

Modelica.Blocks.Interfaces.RealInput mWat_flow(unit="kg/s");

parameter Boolean use_mWat_flow

;

parameter Boolean allowFlowReversal=true

;

equation

connect(conEqn.port_b, sin.ports[1]);

connect(conEqn.port_a, bou.ports[1]);

connect(Q_flow, conEqn.Q_flow);

connect(mWat_flow, conEqn.mWat_flow);

end SubModel;

http://iea-annex60.org

Annex60.Fluid.Interfaces.Examples.ConservationEquation

Annex60.Fluid.Interfaces.Examples.ConservationEquation

Annex60.Fluid.Interfaces.Examples.FourPortHeatMassExchanger

Annex60.Fluid.Interfaces.Examples.FourPortHeatMassExchanger

Annex60.Fluid.Interfaces.Examples.HeaterCooler_u

Annex60.Fluid.Interfaces.Examples.HeaterCooler_u

Annex60.Fluid.Interfaces.Examples.Humidifier_u

Annex60.Fluid.Interfaces.Examples.Humidifier_u

Annex60.Fluid.Interfaces.Examples.PrescribedOutletState

Annex60.Fluid.Interfaces.Examples.PrescribedOutletState

Annex60.Fluid.Interfaces.Examples.ReverseFlowHumidifier

Annex60.Fluid.Interfaces.Examples.ReverseFlowHumidifier

Annex60.Fluid.Interfaces.Examples.ReverseFlowMassExchanger

Annex60.Fluid.Interfaces.Examples.ReverseFlowMassExchanger

Annex60.Fluid.Interfaces.Examples.StaticTwoPortConservationEquation

Annex60.Fluid.Interfaces.Examples.StaticTwoPortConservationEquation

Annex60.Fluid.Interfaces.Examples.Humidifier_u.Humidifier

Annex60.Fluid.Interfaces.Examples.Humidifier_u.Humidifier

Annex60.Fluid.Interfaces.Examples.StaticTwoPortConservationEquation.SubModel

Annex60.Fluid.Interfaces.Examples.StaticTwoPortConservationEquation.SubModel