Collection of models that illustrate model use and test models

Information

This package contains examples for the use of models that can be found in

Annex60.Fluid.Actuators.Dampers.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

Package Content

| Name |

Description |

Damper Damper

|

Damper with constant pressure difference and varying control signal |

MixingBox MixingBox

|

Mixing box with constant pressure difference and varying control signal |

VAVBoxExponential VAVBoxExponential

|

VAV box with constant pressure difference and varying control signal |

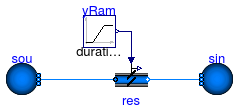

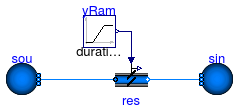

Damper with constant pressure difference and varying control signal

Information

Test model for the air damper.

The air damper is connected to models for constant inlet and outlet

pressures. The control signal of the damper is a ramp.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model Damper

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

Annex60.Fluid.Actuators.Dampers.Exponential res(

A=1,

redeclare package Medium = Medium,

m_flow_nominal=1,

filteredOpening=false);

Modelica.Blocks.Sources.Ramp yRam(

duration=0.3,

offset=0,

startTime=0.2,

height=1);

Annex60.Fluid.Sources.Boundary_pT sou(

redeclare package Medium =

Medium,

nPorts=1,

p(displayUnit="Pa") = 101335,

T=293.15);

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium =

Medium,

nPorts=1,

p(displayUnit="Pa") = 101325,

T=293.15);

equation

connect(yRam.y, res.y);

connect(sou.ports[1], res.port_a);

connect(sin.ports[1], res.port_b);

end Damper;

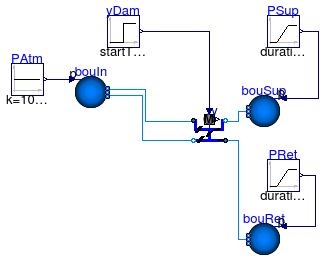

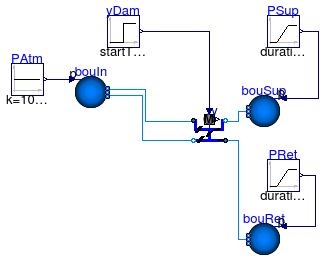

Mixing box with constant pressure difference and varying control signal

Information

Test model for the economizer mixing box.

The economizer mixing box is exposed to time varying pressure boundary

conditions and input signals.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model MixingBox

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air

;

Dampers.MixingBox mixBox(

AOut=0.7,

AExh=1,

ARec=1,

mOut_flow_nominal=1,

dpOut_nominal=20,

mRec_flow_nominal=1,

dpRec_nominal=20,

mExh_flow_nominal=1,

dpExh_nominal=20,

redeclare package Medium = Medium) ;

Annex60.Fluid.Sources.Boundary_pT bouIn(

redeclare package

Medium = Medium, T=273.15 + 10,

use_p_in=true,

nPorts=2);

Annex60.Fluid.Sources.Boundary_pT bouSup(

redeclare package

Medium = Medium, T=273.15 + 26,

use_p_in=true,

nPorts=1);

Annex60.Fluid.Sources.Boundary_pT bouRet(

redeclare package

Medium = Medium, T=273.15 + 20,

use_p_in=true,

nPorts=1);

Modelica.Blocks.Sources.Constant PAtm(k=101325);

Modelica.Blocks.Sources.Ramp PSup(

offset=101320,

height=-10,

startTime=0,

duration=20);

Modelica.Blocks.Sources.Ramp PRet(

height=10,

offset=101330,

duration=20,

startTime=20);

Modelica.Blocks.Sources.Step yDam(

height=1,

offset=0,

startTime=60);

equation

connect(yDam.y, mixBox.y);

connect(bouIn.p_in, PAtm.y);

connect(PRet.y, bouRet.p_in);

connect(bouSup.p_in, PSup.y);

connect(bouIn.ports[1], mixBox.port_Out);

connect(bouIn.ports[2], mixBox.port_Exh);

connect(bouSup.ports[1], mixBox.port_Sup);

connect(bouRet.ports[1], mixBox.port_Ret);

end MixingBox;

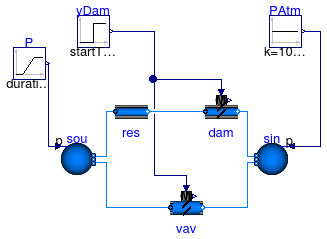

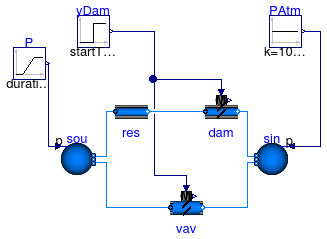

VAV box with constant pressure difference and varying control signal

Information

Test model for the variable air volume flow box.

The model has two flow legs, both are connected to models for constant inlet and outlet

pressures.

The top flow leg has a flow resistance and an air damper, and

the bottom flow leg combines both of these resistances into one model.

Both flow legs have identical mass flow rates, except at very small

flow rates. The reason for this difference is that the equations

are regularized for numerical reasons, and combining the two components

within one component leads to a slightly different equation for the

regularization.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model VAVBoxExponential

extends Modelica.Icons.Example;

package Medium =

Annex60.Media.Air;

Annex60.Fluid.Actuators.Dampers.Exponential dam(

redeclare package Medium = Medium, A=1.8,

m_flow_nominal=2);

Modelica.Blocks.Sources.Step yDam(

height=-1,

offset=1,

startTime=60);

Modelica.Blocks.Sources.Ramp P(

height=-10,

offset=101330,

startTime=0,

duration=60);

Annex60.Fluid.Sources.Boundary_pT sou(

redeclare package Medium =

Medium, T=273.15 + 20,

nPorts=2,

use_p_in=true);

Annex60.Fluid.Sources.Boundary_pT sin(

redeclare package Medium =

Medium, T=273.15 + 20,

nPorts=2,

use_p_in=true);

Modelica.Blocks.Sources.Constant PAtm(k=101325);

Annex60.Fluid.Actuators.Dampers.VAVBoxExponential vav(

redeclare package Medium = Medium,

dp_nominal=5,

A=1.8,

m_flow_nominal=2);

Annex60.Fluid.FixedResistances.PressureDrop res(

from_dp=true,

m_flow_nominal=2,

redeclare package Medium = Medium,

dp_nominal=5 - 0.45*2^2/1.2/1.8^2/2);

equation

connect(yDam.y,dam. y);

connect(P.y, sou.p_in);

connect(PAtm.y, sin.p_in);

connect(yDam.y, vav.y);

connect(res.port_b, dam.port_a);

connect(sou.ports[1], res.port_a);

connect(sou.ports[2], vav.port_a);

connect(dam.port_b, sin.ports[1]);

connect(sin.ports[2], vav.port_b);

end VAVBoxExponential;

http://iea-annex60.org

Annex60.Fluid.Actuators.Dampers.Examples.Damper

Annex60.Fluid.Actuators.Dampers.Examples.Damper

Annex60.Fluid.Actuators.Dampers.Examples.MixingBox

Annex60.Fluid.Actuators.Dampers.Examples.MixingBox

Annex60.Fluid.Actuators.Dampers.Examples.VAVBoxExponential

Annex60.Fluid.Actuators.Dampers.Examples.VAVBoxExponential