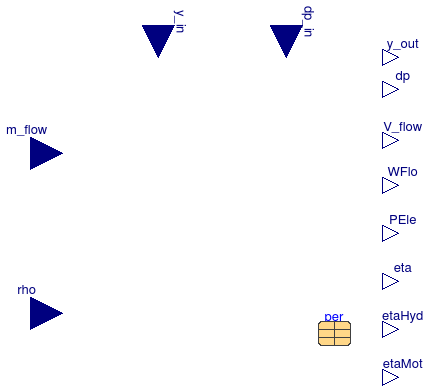

This is an interface that implements the functions to compute the head, power draw

and efficiency of fans and pumps.

The nominal hydraulic characteristic (volume flow rate versus total pressure)

is given by a set of data points

using the data record per, which is an instance of

Annex60.Fluid.Movers.Data.Generic.

A cubic hermite spline with linear extrapolation is used to compute

the performance at other operating points.

For numerical reasons, the user-provided data points for volume flow rate

versus pressure rise are modified to add a fan internal flow resistance.

Because this flow resistance is subtracted during the simulation when

computing the fan pressure rise, the model reproduces the exact points

that were provided by the user.

Also for numerical reasons, the pressure rise at zero flow rate and

the flow rate at zero pressure rise is added to the user-provided data,

unless the user already provides these data points.

Since Modelica 3.2 does not allow dynamic memory allocation, this

implementation required the use of three different arrays for the

situation where no additional point is added, where one additional

point is added and where two additional points are added.

The parameter curve causes the correct data record

to be used during the simulation.

model FlowMachineInterface

extends Modelica.Blocks.Interfaces.BlockIcon;

import cha =

Annex60.Fluid.Movers.BaseClasses.Characteristics;

parameter Annex60.Fluid.Movers.Data.Generic per

;

parameter Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable preVar=

Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed ;

parameter Boolean computePowerUsingSimilarityLaws

;

final parameter Modelica.SIunits.VolumeFlowRate V_flow_nominal=

per.pressure.V_flow[nOri] ;

parameter Modelica.SIunits.Density rho_default

;

parameter Boolean haveVMax

;

parameter Modelica.SIunits.VolumeFlowRate V_flow_max

;

parameter Integer nOri(min=1) ;

parameter Boolean homotopyInitialization = true ;

Modelica.Blocks.Interfaces.RealInput y_in(

final unit="1")

if preSpe

;

Modelica.Blocks.Interfaces.RealOutput y_out(

final unit="1") ;

Modelica.Blocks.Interfaces.RealInput m_flow(

final quantity="MassFlowRate",

final unit="kg/s") ;

Modelica.Blocks.Interfaces.RealInput rho(

final quantity="Density",

final unit="kg/m3",

min=0.0) ;

Modelica.Blocks.Interfaces.RealOutput V_flow(

quantity="VolumeFlowRate",

final unit="m3/s") ;

Modelica.Blocks.Interfaces.RealInput dp_in(

quantity="PressureDifference",

final unit="Pa")

if prePre ;

Modelica.Blocks.Interfaces.RealOutput dp(

quantity="Pressure",

final unit="Pa")

if not prePre ;

Modelica.Blocks.Interfaces.RealOutput WFlo(

quantity="Power",

final unit="W") ;

Modelica.Blocks.Interfaces.RealOutput PEle(

quantity="Power",

final unit="W") ;

Modelica.Blocks.Interfaces.RealOutput eta(

final quantity="Efficiency",

final unit="1") ;

Modelica.Blocks.Interfaces.RealOutput etaHyd(

final quantity="Efficiency",

final unit="1") ;

Modelica.Blocks.Interfaces.RealOutput etaMot(

final quantity="Efficiency",

final unit="1") ;

Modelica.Blocks.Interfaces.RealOutput r_N(unit="1")

;

Real r_V(start=1, unit="1") ;

protected

final parameter Boolean preSpe=

preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed

;

final parameter Boolean prePre=

preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.PressureDifference

or

preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.FlowRate

;

final parameter Real motDer[

size(per.motorEfficiency.V_flow, 1)](

each fixed=false)

;

final parameter Real hydDer[

size(per.hydraulicEfficiency.V_flow,1)](

each fixed=false)

;

parameter Modelica.SIunits.PressureDifference dpMax(displayUnit="Pa")=

if haveDPMax

then

per.pressure.dp[1]

else

per.pressure.dp[1] - ((per.pressure.dp[2] - per.pressure.dp[1])/(

per.pressure.V_flow[2] - per.pressure.V_flow[1]))*per.pressure.V_flow[1]

;

parameter Real delta = 0.05

;

parameter Real kRes(min=0, unit="kg/(s.m4)") = dpMax/V_flow_max*delta^2/10

;

parameter Integer curve=

if (haveVMax

and haveDPMax)

or (nOri == 2)

then 1

elseif haveVMax

or haveDPMax

then 2

else 3

;

final parameter Annex60.Fluid.Movers.BaseClasses.Characteristics.flowParametersInternal

pCur1(

final n = nOri,

final V_flow =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

{per.pressure.V_flow[i]

for i

in 1:nOri}

else

zeros(nOri),

final dp =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

{(per.pressure.dp[i] + per.pressure.V_flow[i] * kRes)

for i

in 1:nOri}

else

zeros(nOri))

;

parameter Annex60.Fluid.Movers.BaseClasses.Characteristics.flowParametersInternal

pCur2(

final n = nOri + 1,

V_flow =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

zeros(nOri + 1)

elseif haveVMax

then

cat(1, {0}, {per.pressure.V_flow[i]

for i

in 1:nOri})

elseif haveDPMax

then

cat(1, { per.pressure.V_flow[i]

for i

in 1:nOri}, {V_flow_max})

else

zeros(nOri + 1),

dp =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

zeros(nOri + 1)

elseif haveVMax

then

cat(1, {dpMax}, {per.pressure.dp[i] + per.pressure.V_flow[i] * kRes

for i

in 1:nOri})

elseif haveDPMax

then

cat(1, {per.pressure.dp[i] + per.pressure.V_flow[i] * kRes

for i

in 1:nOri}, {0})

else

zeros(nOri+1))

;

parameter Annex60.Fluid.Movers.BaseClasses.Characteristics.flowParametersInternal

pCur3(

final n = nOri + 2,

V_flow =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

zeros(nOri + 2)

elseif haveVMax

or haveDPMax

then

zeros(nOri + 2)

else

cat(1, {0}, {per.pressure.V_flow[i]

for i

in 1:nOri}, {V_flow_max}),

dp =

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

zeros(nOri + 2)

elseif haveVMax

or haveDPMax

then

zeros(nOri + 2)

else

cat(1, {dpMax}, {per.pressure.dp[i] + per.pressure.V_flow[i] * kRes

for i

in 1:nOri}, {0}))

;

parameter Real preDer1[nOri](

each fixed=false)

;

parameter Real preDer2[nOri+1](

each fixed=false)

;

parameter Real preDer3[nOri+2](

each fixed=false)

;

parameter Real powDer[

size(per.power.V_flow,1)]=

if per.use_powerCharacteristic

then

Annex60.Utilities.Math.Functions.splineDerivatives(

x=per.power.V_flow,

y=per.power.P,

ensureMonotonicity=

Annex60.Utilities.Math.Functions.isMonotonic(x=per.power.P,

strict=false))

else

zeros(

size(per.power.V_flow,1))

;

parameter Boolean haveMinimumDecrease=

Modelica.Math.BooleanVectors.allTrue({(per.pressure.dp[i + 1] -

per.pressure.dp[i])/(per.pressure.V_flow[i + 1] - per.pressure.V_flow[

i]) < -kRes

for i

in 1:nOri - 1}) ;

parameter Boolean haveDPMax = (

abs(per.pressure.V_flow[1]) < Modelica.Constants.eps)

;

Modelica.Blocks.Interfaces.RealOutput dp_internal

;

function getPerformanceDataAsString

input Annex60.Fluid.Movers.BaseClasses.Characteristics.flowParameters pressure

;

input Real derivative[:](unit="kg/(s.m4)") ;

input Integer minimumLength = 6 ;

input Integer significantDigits = 6 ;

output String str ;

algorithm

str :="";

for i

in 1:

size(derivative, 1)

loop

str :=str + " V_flow[" +

String(i) + "]=" +

String(

pressure.V_flow[i],

minimumLength=minimumLength,

significantDigits=significantDigits) + "\t" + "dp[" +

String(i) + "]=" +

String(

pressure.dp[i],

minimumLength=minimumLength,

significantDigits=significantDigits) + "\tResulting derivative dp/dV_flow = "

+

String(

derivative[i],

minimumLength=minimumLength,

significantDigits=significantDigits) + "\n";

end for;

end getPerformanceDataAsString;

function getArrayAsString

input Real array[:] ;

input String varName ;

input Integer minimumLength = 6 ;

input Integer significantDigits = 6 ;

output String str ;

algorithm

str :="";

for i

in 1:

size(array, 1)

loop

str :=str + " " + varName + "[" +

String(i) + "]=" +

String(

array[i],

minimumLength=minimumLength,

significantDigits=significantDigits) + "\n";

end for;

end getArrayAsString;

initial equation

assert(nOri > 1, "Must have at least two data points for pressure.V_flow.");

assert(

Annex60.Utilities.Math.Functions.isMonotonic(x=per.pressure.V_flow, strict=true)

and

per.pressure.V_flow[1] > -Modelica.Constants.eps,

"The fan pressure rise must be a strictly decreasing sequence with respect to the volume flow rate,

with the first element for the fan pressure raise being non-zero.

The following performance data have been entered:

" +

getArrayAsString(per.pressure.V_flow, "pressure.V_flow"));

if not haveVMax

then

assert((per.pressure.V_flow[nOri]-per.pressure.V_flow[nOri-1])

/((per.pressure.dp[nOri]-per.pressure.dp[nOri-1]))<0,

"The last two pressure points for the fan or pump performance curve must be decreasing.

You need to set more reasonable parameters.

Received

" +

getArrayAsString(per.pressure.dp, "dp"));

end if;

if (

not haveMinimumDecrease)

then

Modelica.Utilities.Streams.print("

Warning:

========

It is recommended that the volume flow rate versus pressure relation

of the fan or pump satisfies the minimum decrease condition

(per.pressure.dp[i+1]-per.pressure.dp[i])

d[i] = ------------------------------------------------- < " +

String(-kRes) + "

(per.pressure.V_flow[i+1]-per.pressure.V_flow[i])

is

" +

getArrayAsString({(per.pressure.dp[i+1]-per.pressure.dp[i])

/(per.pressure.V_flow[i+1]-per.pressure.V_flow[i])

for i

in 1:nOri-1}, "d") + "

Otherwise, a solution to the equations may not exist if the fan or pump speed is reduced.

In this situation, the solver will fail due to non-convergence and

the simulation stops.");

end if;

if (haveVMax

and haveDPMax)

or (nOri == 2)

then

preDer1=

Annex60.Utilities.Math.Functions.splineDerivatives(x=pCur1.V_flow,

y=pCur1.dp);

preDer2=

zeros(nOri + 1);

preDer3=

zeros(nOri + 2);

elseif haveVMax

or haveDPMax

then

preDer1=

zeros(nOri);

preDer2=

Annex60.Utilities.Math.Functions.splineDerivatives(x=pCur2.V_flow,

y=pCur2.dp);

preDer3=

zeros(nOri + 2);

else

preDer1=

zeros(nOri);

preDer2=

zeros(nOri + 1);

preDer3=

Annex60.Utilities.Math.Functions.splineDerivatives(x=pCur3.V_flow,

y=pCur3.dp);

end if;

motDer =

if per.use_powerCharacteristic

then zeros(

size(per.motorEfficiency.V_flow,

1))

elseif (

size(per.motorEfficiency.V_flow, 1) == 1)

then {0}

else

Annex60.Utilities.Math.Functions.splineDerivatives(

x=per.motorEfficiency.V_flow,

y=per.motorEfficiency.eta,

ensureMonotonicity=

Annex60.Utilities.Math.Functions.isMonotonic(x=per.motorEfficiency.eta,

strict=false));

hydDer =

if per.use_powerCharacteristic

then zeros(

size(per.hydraulicEfficiency.V_flow,

1))

elseif (

size(per.hydraulicEfficiency.V_flow, 1) == 1)

then {0}

else Annex60.Utilities.Math.Functions.splineDerivatives(x=per.hydraulicEfficiency.V_flow,

y=per.hydraulicEfficiency.eta);

equation

connect(dp_internal,dp);

connect(dp_internal,dp_in);

connect(r_N, y_in);

y_out=r_N;

V_flow = m_flow/rho;

r_V = V_flow/V_flow_max;

if (computePowerUsingSimilarityLaws == false)

and preVar <> Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed

then

r_N=1;

else

if (curve == 1)

then

if homotopyInitialization

then

V_flow*kRes + dp_internal =

homotopy(actual=

cha.pressure(

V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer1,

per=pCur1),

simplified=r_N * (

cha.pressure(

V_flow=V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer1,

per=pCur1)

+(V_flow-V_flow_nominal) * (

cha.pressure(

V_flow=(1+delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer1,

per=pCur1)

-

cha.pressure(V_flow=(1-delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer1,

per=pCur1))

/(2*delta*V_flow_nominal)));

else

V_flow*kRes + dp_internal=

cha.pressure(V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer1,

per=pCur1);

end if;

elseif (curve == 2)

then

if homotopyInitialization

then

V_flow*kRes + dp_internal =

homotopy(actual=

cha.pressure(

V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer2,

per=pCur2),

simplified=r_N * (

cha.pressure(

V_flow=V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer2,

per=pCur2)

+(V_flow-V_flow_nominal) * (

cha.pressure(

V_flow=(1+delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer2,

per=pCur2)

-

cha.pressure(V_flow=(1-delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer2,

per=pCur2))

/(2*delta*V_flow_nominal)));

else

V_flow*kRes + dp_internal=

cha.pressure(V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer2,

per=pCur2);

end if;

else

if homotopyInitialization

then

V_flow*kRes + dp_internal =

homotopy(actual=

cha.pressure(

V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer3,

per=pCur3),

simplified=r_N * (

cha.pressure(

V_flow=V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer3,

per=pCur3)

+(V_flow-V_flow_nominal)*

(

cha.pressure(V_flow=(1+delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer3,

per=pCur3)

-

cha.pressure(V_flow=(1-delta)*V_flow_nominal,

r_N=1,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer3,

per=pCur3))

/(2*delta*V_flow_nominal)));

else

V_flow*kRes + dp_internal=

cha.pressure(V_flow=V_flow,

r_N=r_N,

dpMax=dpMax,

V_flow_max=V_flow_max,

d=preDer3,

per=pCur3);

end if;

end if;

end if;

WFlo = dp_internal*V_flow;

if per.use_powerCharacteristic

then

if homotopyInitialization

then

PEle =

homotopy(actual=

cha.power(per=per.power, V_flow=V_flow, r_N=r_N, d=powDer, delta=delta),

simplified=V_flow/V_flow_nominal*

cha.power(per=per.power, V_flow=V_flow_nominal, r_N=1, d=powDer, delta=delta));

else

PEle = (rho/rho_default)*

cha.power(per=per.power, V_flow=V_flow, r_N=r_N, d=powDer, delta=delta);

end if;

eta = WFlo /

Annex60.Utilities.Math.Functions.smoothMax(x1=PEle, x2=1E-5, deltaX=1E-6);

etaHyd = 1;

etaMot = eta;

else

if homotopyInitialization

then

etaHyd =

homotopy(actual=

cha.efficiency(per=per.hydraulicEfficiency, V_flow=V_flow, d=hydDer, r_N=r_N, delta=delta),

simplified=

cha.efficiency(per=per.hydraulicEfficiency, V_flow=V_flow_max, d=hydDer, r_N=r_N, delta=delta));

etaMot =

homotopy(actual=

cha.efficiency(per=per.motorEfficiency, V_flow=V_flow, d=motDer, r_N=r_N, delta=delta),

simplified=

cha.efficiency(per=per.motorEfficiency, V_flow=V_flow_max, d=motDer, r_N=r_N, delta=delta));

else

etaHyd =

cha.efficiency(per=per.hydraulicEfficiency, V_flow=V_flow, d=hydDer, r_N=r_N, delta=delta);

etaMot =

cha.efficiency(per=per.motorEfficiency, V_flow=V_flow, d=motDer, r_N=r_N, delta=delta);

end if;

PEle = WFlo /

Annex60.Utilities.Math.Functions.smoothMax(x1=eta, x2=1E-5, deltaX=1E-6);

eta = etaHyd * etaMot;

end if;

end FlowMachineInterface;

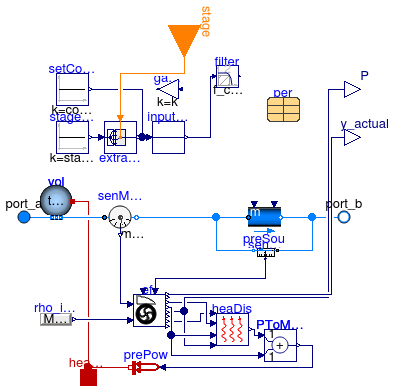

Model of a fictitious pipe that is used as a base class

for a pressure source or to prescribe a mass flow rate.

Note that for fans and pumps with dynamic balance,

both the heat and the flow work are added to the volume of

air or water. This simplifies the equations compared to

adding heat to the volume, and flow work to this model.

This is the base model for fans and pumps.

It provides an interface

between the equations that compute head and power consumption,

and the implementation of the energy and pressure balance

of the fluid.

Optionally, the fluid volume

is computed using a dynamic balance or a steady-state balance.

partial model PartialFlowMachine

extends Annex60.Fluid.Interfaces.LumpedVolumeDeclarations(

final mSenFac=1);

extends Annex60.Fluid.Interfaces.PartialTwoPortInterface(

show_T=false,

port_a(

h_outflow(start=h_outflow_start)),

port_b(

h_outflow(start=h_outflow_start),

p(start=p_start),

final m_flow(max =

if allowFlowReversal

then +Modelica.Constants.inf

else 0)));

replaceable parameter Annex60.Fluid.Movers.Data.Generic per

constrainedby Annex60.Fluid.Movers.Data.Generic

;

parameter Annex60.Fluid.Types.InputType inputType = Annex60.Fluid.Types.InputType.Continuous

;

parameter Real constInput = 0 ;

parameter Real stageInputs[:]

;

parameter Boolean computePowerUsingSimilarityLaws

;

parameter Boolean addPowerToMedium=true

;

parameter Boolean nominalValuesDefineDefaultPressureCurve = false

;

parameter Modelica.SIunits.Time tau=1

;

parameter Boolean filteredSpeed=true

;

parameter Modelica.SIunits.Time riseTime=30

;

parameter Modelica.Blocks.Types.Init init=Modelica.Blocks.Types.Init.InitialOutput

;

parameter Real y_start(min=0, max=1, unit="1")=0 ;

Modelica.Blocks.Interfaces.IntegerInput stage

if

inputType == Annex60.Fluid.Types.InputType.Stages

;

Modelica.Blocks.Interfaces.RealOutput y_actual(

final unit="1")

;

Modelica.Blocks.Interfaces.RealOutput P(

quantity="Power",

final unit="W") ;

Modelica.Thermal.HeatTransfer.Interfaces.HeatPort_a heatPort

;

Modelica.SIunits.VolumeFlowRate VMachine_flow(start=_VMachine_flow) = eff.V_flow ;

Modelica.SIunits.PressureDifference dpMachine(displayUnit="Pa")=

-preSou.dp ;

Real eta(unit="1",

final quantity="Efficiency") = eff.eta ;

Real etaHyd(unit="1",

final quantity="Efficiency") = eff.etaHyd ;

Real etaMot(unit="1",

final quantity="Efficiency") = eff.etaMot ;

protected

final parameter Modelica.SIunits.VolumeFlowRate _VMachine_flow = 0

;

parameter Types.PrescribedVariable preVar ;

final parameter Boolean speedIsInput=

(preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed)

;

final parameter Integer nOri =

size(per.pressure.V_flow, 1)

;

final parameter Boolean haveVMax = (

abs(per.pressure.dp[nOri]) < Modelica.Constants.eps)

;

final parameter Modelica.SIunits.VolumeFlowRate V_flow_max=

if per.havePressureCurve

then

(

if haveVMax

then

per.pressure.V_flow[nOri]

else

per.pressure.V_flow[nOri] - (per.pressure.V_flow[nOri] - per.pressure.V_flow[

nOri - 1])/((per.pressure.dp[nOri] - per.pressure.dp[nOri - 1]))*per.pressure.dp[nOri])

else

m_flow_nominal/rho_default ;

final parameter Modelica.SIunits.Density rho_default=

Medium.density_pTX(

p=Medium.p_default,

T=Medium.T_default,

X=Medium.X_default) ;

final parameter Medium.ThermodynamicState sta_start=

Medium.setState_pTX(

T=T_start,

p=p_start,

X=X_start) ;

final parameter Modelica.SIunits.SpecificEnthalpy h_outflow_start =

Medium.specificEnthalpy(sta_start)

;

Modelica.Blocks.Sources.Constant[

size(stageInputs, 1)] stageValues(

final k=stageInputs)

if

inputType == Annex60.Fluid.Types.InputType.Stages ;

Modelica.Blocks.Sources.Constant setConst(

final k=constInput)

if

inputType == Annex60.Fluid.Types.InputType.Constant

;

Extractor extractor(

final nin=

size(stageInputs,1))

if

inputType == Annex60.Fluid.Types.InputType.Stages ;

Modelica.Blocks.Routing.RealPassThrough inputSwitch

;

Annex60.Fluid.Delays.DelayFirstOrder vol(

redeclare final package Medium =

Medium,

final tau=tau,

final energyDynamics=energyDynamics,

final massDynamics=massDynamics,

final T_start=T_start,

final X_start=X_start,

final C_start=C_start,

final m_flow_nominal=m_flow_nominal,

final m_flow_small=m_flow_small,

final p_start=p_start,

final prescribedHeatFlowRate=true,

final allowFlowReversal=allowFlowReversal,

nPorts=2) ;

Modelica.Blocks.Continuous.Filter filter(

order=2,

f_cut=5/(2*Modelica.Constants.pi*riseTime),

final init=init,

x(

each stateSelect=StateSelect.always),

final analogFilter=Modelica.Blocks.Types.AnalogFilter.CriticalDamping,

final filterType=Modelica.Blocks.Types.FilterType.LowPass)

if

filteredSpeed

;

Modelica.Blocks.Math.Gain gaiSpe(y(

final unit="1"))

if

inputType == Annex60.Fluid.Types.InputType.Continuous

and

speedIsInput

;

Annex60.Fluid.Movers.BaseClasses.IdealSource preSou(

redeclare final package Medium =

Medium,

final m_flow_small=m_flow_small,

final allowFlowReversal=allowFlowReversal,

final control_m_flow= (preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.FlowRate))

;

Annex60.Fluid.Movers.BaseClasses.PowerInterface heaDis(

final motorCooledByFluid=per.motorCooledByFluid,

final delta_V_flow=1E-3*V_flow_max)

if

addPowerToMedium ;

Modelica.Blocks.Math.Add PToMed(

final k1=1,

final k2=1)

if

addPowerToMedium ;

Modelica.Thermal.HeatTransfer.Sources.PrescribedHeatFlow prePow(

final alpha=0)

if

addPowerToMedium

;

Modelica.Blocks.Sources.RealExpression rho_inlet(y=

Medium.density(

Medium.setState_phX(port_a.p,

inStream(port_a.h_outflow),

inStream(port_a.Xi_outflow))))

;

Annex60.Fluid.Sensors.MassFlowRate senMasFlo(

redeclare final package Medium =

Medium) ;

Sensors.RelativePressure senRelPre(

redeclare final package Medium =

Medium) ;

FlowMachineInterface eff(

per(

final hydraulicEfficiency = per.hydraulicEfficiency,

final motorEfficiency = per.motorEfficiency,

final motorCooledByFluid = per.motorCooledByFluid,

final speed_nominal = 0,

final constantSpeed = 0,

final speeds = {0},

final power = per.power),

final nOri = nOri,

final rho_default=rho_default,

final computePowerUsingSimilarityLaws=computePowerUsingSimilarityLaws,

final haveVMax=haveVMax,

final V_flow_max=V_flow_max,

r_N(start=y_start),

r_V(start=m_flow_nominal/rho_default),

final preVar=preVar) ;

protected

block Extractor

extends Modelica.Blocks.Interfaces.MISO;

Modelica.Blocks.Interfaces.IntegerInput index ;

equation

y =

sum({

if index == i

then u[i]

else 0

for i

in 1:nin});

end Extractor;

initial equation

assert(nominalValuesDefineDefaultPressureCurve

or

per.havePressureCurve

or

(preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed),

"*** Warning: You are using a flow or pressure controlled mover with the

default pressure curve.

This leads to approximate calculations of the electrical power

consumption. Add the correct pressure curve in the record per

to obtain an accurate computation.

Setting nominalValuesDefineDefaultPressureCurve=true will suppress this warning.",

level=AssertionLevel.warning);

assert(nominalValuesDefineDefaultPressureCurve

or

(per.havePressureCurve

or

(preVar == Annex60.Fluid.Movers.BaseClasses.Types.PrescribedVariable.Speed))

or

per.use_powerCharacteristic == false,

"*** Warning: You are using a flow or pressure controlled mover with the

default pressure curve and you set use_powerCharacteristic = true.

Since this can cause wrong power consumption, the model will overwrite

this setting and use instead use_powerCharacteristic = false.

Since this causes the efficiency curve to be used,

make sure that the efficiency curves in the performance record per

are correct or add the pressure curve of the mover.

Setting nominalValuesDefineDefaultPressureCurve=true will suppress this warning.",

level=AssertionLevel.warning);

equation

connect(prePow.port, vol.heatPort);

connect(vol.heatPort, heatPort);

connect(preSou.port_b, port_b);

connect(stageValues.y, extractor.u);

connect(extractor.y, inputSwitch.u);

connect(setConst.y, inputSwitch.u);

connect(extractor.index, stage);

connect(PToMed.y, prePow.Q_flow);

connect(PToMed.u1, heaDis.Q_flow);

connect(senRelPre.port_b, preSou.port_a);

connect(senRelPre.port_a, preSou.port_b);

connect(heaDis.etaHyd,eff. etaHyd);

connect(heaDis.V_flow,eff. V_flow);

connect(eff.PEle, heaDis.PEle);

connect(eff.WFlo, heaDis.WFlo);

connect(rho_inlet.y,eff. rho);

connect(eff.m_flow, senMasFlo.m_flow);

connect(eff.PEle, P);

connect(eff.WFlo, PToMed.u2);

connect(inputSwitch.y, filter.u);

connect(senRelPre.p_rel, eff.dp_in);

connect(eff.y_out, y_actual);

connect(port_a, vol.ports[1]);

connect(vol.ports[2], senMasFlo.port_a);

connect(senMasFlo.port_b, preSou.port_a);

end PartialFlowMachine;

Annex60.Fluid.Movers.BaseClasses.FlowMachineInterface

Annex60.Fluid.Movers.BaseClasses.FlowMachineInterface

Annex60.Fluid.Movers.BaseClasses.IdealSource

Annex60.Fluid.Movers.BaseClasses.IdealSource

Annex60.Fluid.Movers.BaseClasses.PartialFlowMachine

Annex60.Fluid.Movers.BaseClasses.PartialFlowMachine

Annex60.Fluid.Movers.BaseClasses.PowerInterface

Annex60.Fluid.Movers.BaseClasses.PowerInterface

Annex60.Fluid.Movers.BaseClasses.PartialFlowMachine.Extractor

Annex60.Fluid.Movers.BaseClasses.PartialFlowMachine.Extractor