| IEA EBC Annex 60 |

|

Collection of models that validate the heat pump models

This package contains models that validate the heat pump models. The examples plot various outputs, which have been verified against analytical solutions. These model outputs are stored as reference data to allow continuous validation whenever models in the library change.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

| Name | Description |

|---|---|

| Test model for Carnot_TCon with limited heating capacity | |

| Test model for Carnot_TCon with low condenser leaving water temperature | |

| Test model for the part load efficiency curve with condenser leaving temperature as input signal | |

| Test model for heat pump based on Carnot efficiency and condenser outlet temperature control signal | |

| Test model for heat pump based on Carnot efficiency with etaCar as parameter | |

| Test model for the part load efficiency curve with compressor speed as input signal |

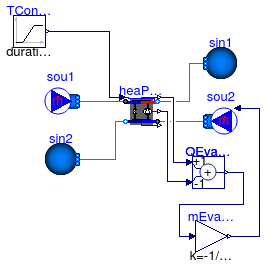

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_LimitedCapacity

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_LimitedCapacity

Test model for Carnot_TCon with limited heating capacity

This example extends from Annex60.Fluid.HeatPumps.Examples.Carnot_TCon but limits the heating capacity.

Extends from Examples.Carnot_TCon (Test model for heat pump based on Carnot efficiency and condenser outlet temperature control signal).

| Type | Name | Default | Description |

|---|---|---|---|

| TemperatureDifference | dTEva_nominal | -5 | Temperature difference evaporator inlet-outlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| HeatFlowRate | QCon_flow_nominal | 100E3 | Evaporator heat flow rate [W] |

| MassFlowRate | m1_flow_nominal | QCon_flow_nominal/dTCon_nomi... | Nominal mass flow rate at condenser [kg/s] |

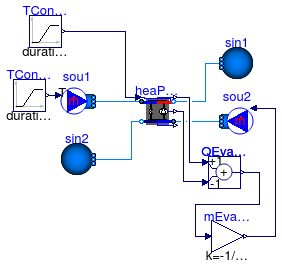

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_LowTemperature

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_LowTemperature

Test model for Carnot_TCon with low condenser leaving water temperature

This example extends from Annex60.Fluid.HeatPumps.Examples.Carnot_TCon but decreases the set point for the leaving condenser temperature to be below its inlet temperature, in which case the model provides no heating. Towards the end of the simulation, the inlet temperature of the condenser is decreased to be below the evaporator temperature. In this domain, the model requires cooling again. While this is not a meaningful operating point for the model, the example verifies that it robustly simulates this regime.

Extends from Examples.Carnot_TCon (Test model for heat pump based on Carnot efficiency and condenser outlet temperature control signal).

| Type | Name | Default | Description |

|---|---|---|---|

| TemperatureDifference | dTEva_nominal | -5 | Temperature difference evaporator inlet-outlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| HeatFlowRate | QCon_flow_nominal | 100E3 | Evaporator heat flow rate [W] |

| MassFlowRate | m1_flow_nominal | QCon_flow_nominal/dTCon_nomi... | Nominal mass flow rate at condenser [kg/s] |

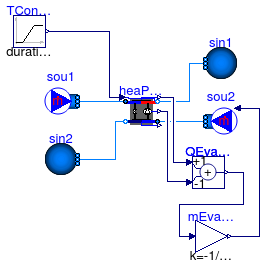

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_etaPL

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_etaPL

Test model for the part load efficiency curve with condenser leaving temperature as input signal

This example extends from Annex60.Fluid.HeatPumps.Examples.Carnot_TCon but has a part load efficiency that varies with the load.

Extends from Examples.Carnot_TCon (Test model for heat pump based on Carnot efficiency and condenser outlet temperature control signal).

| Type | Name | Default | Description |

|---|---|---|---|

| TemperatureDifference | dTEva_nominal | -5 | Temperature difference evaporator inlet-outlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| HeatFlowRate | QCon_flow_nominal | 100E3 | Evaporator heat flow rate [W] |

| MassFlowRate | m1_flow_nominal | QCon_flow_nominal/dTCon_nomi... | Nominal mass flow rate at condenser [kg/s] |

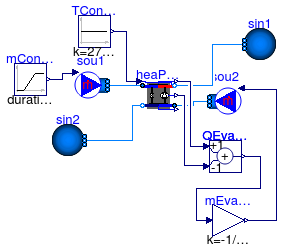

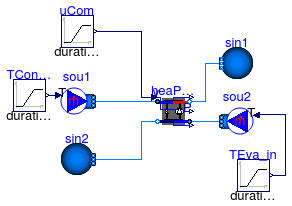

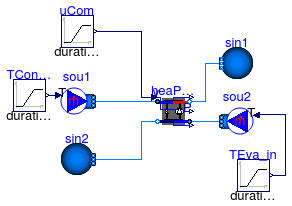

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_reverseFlow

Annex60.Fluid.HeatPumps.Validation.Carnot_TCon_reverseFlow

Test model for heat pump based on Carnot efficiency and condenser outlet temperature control signal

Example that simulates a heat pump whose efficiency is scaled based on the

Carnot cycle.

The heat pump takes as an input the condenser leaving water temperature.

The condenser mass flow rate is computed in such a way that it has

a temperature difference equal to dTCon_nominal.

This example checks the correct behavior if a mass flow rate attains zero.

Extends from Modelica.Icons.Example (Icon for runnable examples).

| Type | Name | Default | Description |

|---|---|---|---|

| TemperatureDifference | dTEva_nominal | -10 | Temperature difference evaporator inlet-outlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| HeatFlowRate | QCon_flow_nominal | 100E3 | Evaporator heat flow rate [W] |

| MassFlowRate | m1_flow_nominal | QCon_flow_nominal/dTCon_nomi... | Nominal mass flow rate at condenser [kg/s] |

Annex60.Fluid.HeatPumps.Validation.Carnot_y_etaCar

Annex60.Fluid.HeatPumps.Validation.Carnot_y_etaCar

Test model for heat pump based on Carnot efficiency with etaCar as parameter

This example extends from

Annex60.Fluid.HeatPumps.Examples.Carnot_y

but uses the parameter etaCar instead of COP_nominal.

Extends from Annex60.Fluid.HeatPumps.Examples.Carnot_y (Test model for heat pump based on Carnot efficiency).

| Type | Name | Default | Description |

|---|---|---|---|

| Real | COP_nominal | 6 | Nominal COP |

| Power | P_nominal | 10E3 | Nominal compressor power (at y=1) [W] |

| TemperatureDifference | dTEva_nominal | -10 | Temperature difference evaporator outlet-inlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| MassFlowRate | m2_flow_nominal | -P_nominal*(COP_nominal - 1)... | Nominal mass flow rate at chilled water side [kg/s] |

| MassFlowRate | m1_flow_nominal | P_nominal*COP_nominal/cp1_de... | Nominal mass flow rate at condenser water wide [kg/s] |

Annex60.Fluid.HeatPumps.Validation.Carnot_y_etaPL

Annex60.Fluid.HeatPumps.Validation.Carnot_y_etaPL

Test model for the part load efficiency curve with compressor speed as input signal

This example extends from Annex60.Fluid.HeatPumps.Examples.Carnot_y but uses a part load efficiency curve that is different from 1.

Extends from Examples.Carnot_y (Test model for heat pump based on Carnot efficiency).

| Type | Name | Default | Description |

|---|---|---|---|

| Real | COP_nominal | 6 | Nominal COP |

| Power | P_nominal | 10E3 | Nominal compressor power (at y=1) [W] |

| TemperatureDifference | dTEva_nominal | -10 | Temperature difference evaporator outlet-inlet [K] |

| TemperatureDifference | dTCon_nominal | 10 | Temperature difference condenser outlet-inlet [K] |

| MassFlowRate | m2_flow_nominal | -P_nominal*(COP_nominal - 1)... | Nominal mass flow rate at chilled water side [kg/s] |

| MassFlowRate | m1_flow_nominal | P_nominal*COP_nominal/cp1_de... | Nominal mass flow rate at condenser water wide [kg/s] |