Collection of models that illustrate model use and test models

Information

This package contains examples for the use of models that can be found in

Annex60.Controls.Continuous.

Extends from Modelica.Icons.ExamplesPackage (Icon for packages containing runnable examples).

Package Content

| Name |

Description |

LimPID LimPID

|

Test model for PID controller with optional reverse action |

LimPIDWithReset LimPIDWithReset

|

Example that demonstrates the controller output reset |

NumberOfRequests NumberOfRequests

|

Example model for block that outputs the number of requests |

OffTimer OffTimer

|

Example model for off timer |

PIDHysteresis PIDHysteresis

|

Example model for PID controller with hysteresis |

PIDHysteresisTimer PIDHysteresisTimer

|

Example model for PID controller with hysteresis and timer |

SignalRanker SignalRanker

|

Example model for signal ranker |

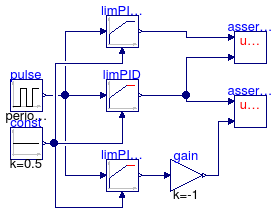

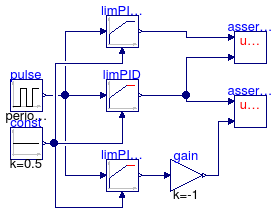

Test model for PID controller with optional reverse action

Information

This model tests the implementation of the

PID controller with optional reverse action.

The model limPIDOri is the original

implementation of the controller from the Modelica

Standard Library. The models limPID

and limPIDRev are the implementations

from the Annex60 library. The model

limPIDRev is parameterized to have

reverse action.

The assertion blocks test whether the results

of all three controllers are identical.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model LimPID

extends Modelica.Icons.Example;

Modelica.Blocks.Sources.Pulse pulse(period=0.25);

Annex60.Controls.Continuous.LimPID limPID(

controllerType=Modelica.Blocks.Types.SimpleController.PID,

Ti=1,

Td=1,

yMax=1,

yMin=-1,

initType=Modelica.Blocks.Types.InitPID.InitialState);

Annex60.Controls.Continuous.LimPID limPIDRev(

controllerType=Modelica.Blocks.Types.SimpleController.PID,

reverseAction=true,

Ti=1,

Td=1,

yMax=1,

yMin=-1,

initType=Modelica.Blocks.Types.InitPID.InitialState)

;

Modelica.Blocks.Sources.Constant const(k=0.5);

Modelica.Blocks.Math.Gain gain(k=-1);

Annex60.Utilities.Diagnostics.AssertEquality assertEquality(

threShold=1e-3);

Modelica.Blocks.Continuous.LimPID limPIDOri(

controllerType=Modelica.Blocks.Types.SimpleController.PID,

Ti=1,

Td=1,

yMax=1,

yMin=-1,

initType=Modelica.Blocks.Types.InitPID.InitialState);

Annex60.Utilities.Diagnostics.AssertEquality assertEquality1(

threShold=1e-3);

equation

connect(pulse.y, limPID.u_s);

connect(pulse.y, limPIDRev.u_s);

connect(const.y, limPID.u_m);

connect(const.y, limPIDRev.u_m);

connect(limPIDRev.y, gain.u);

connect(gain.y, assertEquality.u2);

connect(limPID.y, assertEquality.u1);

connect(pulse.y, limPIDOri.u_s);

connect(const.y, limPIDOri.u_m);

connect(assertEquality1.u1, limPIDOri.y);

connect(assertEquality1.u2, limPID.y);

end LimPID;

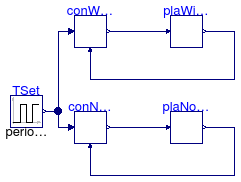

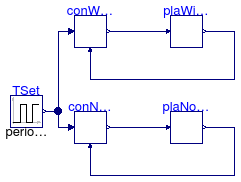

Example that demonstrates the controller output reset

Information

Example that demonstrates the effect

of the integrator reset.

The top model has the reset of the controller output enabled.

By plotting the controller error, one sees that the integrator reset

improves the closed loop performance slightly.

Note, however, that both controllers have an integrator anti-windup

and hence the integrator reset has limited benefits.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model LimPIDWithReset

extends Modelica.Icons.Example;

Plant plaWitRes ;

Controller conWitRes(reset=Annex60.Types.Reset.Parameter)

;

Plant plaNoRes ;

Controller conNoRes(reset=Annex60.Types.Reset.Disabled)

;

Modelica.Blocks.Sources.Pulse TSet(

amplitude=20,

width=50,

offset=293.15,

y(unit="K"),

period=180) ;

protected

model Plant

extends Modelica.Blocks.Icons.Block;

Modelica.Blocks.Interfaces.RealInput Q_flow(unit="W")

;

Modelica.Blocks.Interfaces.RealOutput T(unit="K")

;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap(

C=10,

T(fixed=true,

start=293.15)) ;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap1(

C=10,

T(fixed=true,

start=293.15)) ;

Modelica.Thermal.HeatTransfer.Sensors.TemperatureSensor temSen

;

Modelica.Thermal.HeatTransfer.Sources.PrescribedHeatFlow preHea

;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon(G=5)

;

Modelica.Thermal.HeatTransfer.Sources.FixedTemperature TBou(T=293.15)

;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon1(G=1)

;

equation

connect(Q_flow, preHea.Q_flow);

connect(T, temSen.T);

connect(TBou.port, theCon.port_a);

connect(cap.port, theCon1.port_a);

connect(theCon1.port_b, cap1.port);

connect(cap1.port, temSen.port);

connect(theCon.port_b, cap.port);

connect(preHea.port, cap.port);

end Plant;

model Controller

extends Modelica.Blocks.Icons.Block;

parameter Annex60.Types.Reset reset=Annex60.Types.Reset.Disabled

;

Modelica.Blocks.Interfaces.RealInput TSet(unit="K") ;

Modelica.Blocks.Interfaces.RealInput u_m(unit="K")

;

Modelica.Blocks.Interfaces.RealOutput y

;

Annex60.Controls.Continuous.LimPID conPID(

final reset=reset,

yMax=1,

yMin=0,

controllerType=Modelica.Blocks.Types.SimpleController.PI,

Ti=1,

k=10) ;

Modelica.Blocks.Math.Gain gain(k=5000)

;

Modelica.Blocks.Logical.GreaterThreshold trigger(threshold=303.15)

;

equation

connect(conPID.y,gain. u);

connect(trigger.y,conPID. trigger);

connect(u_m, conPID.u_m);

connect(conPID.u_s, TSet);

connect(trigger.u, TSet);

connect(gain.y, y);

end Controller;

equation

connect(plaWitRes.T, conWitRes.u_m);

connect(conWitRes.y, plaWitRes.Q_flow);

connect(plaNoRes.T, conNoRes.u_m);

connect(conNoRes.y, plaNoRes.Q_flow);

connect(TSet.y, conWitRes.TSet);

connect(TSet.y, conNoRes.TSet);

end LimPIDWithReset;

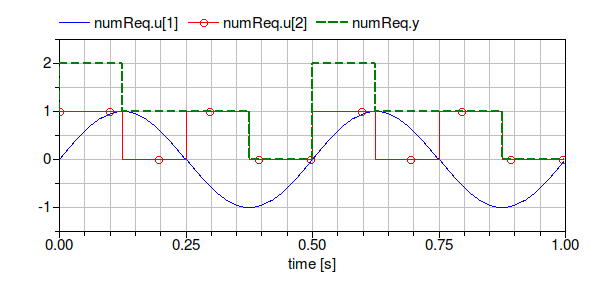

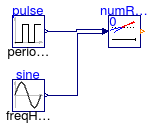

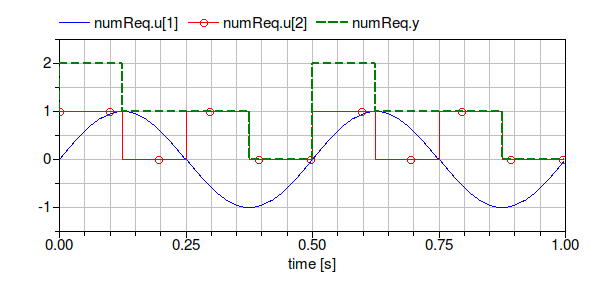

Example model for block that outputs the number of requests

Information

Example that demonstrates the use of the block

Annex60.Controls.Continuous.NumberOfRequests.

The parameters of the block are such that the output is incremented

for each input signal that is strictly larger than 0.

The figure below shows the inputs and the output of the block.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

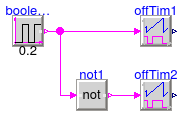

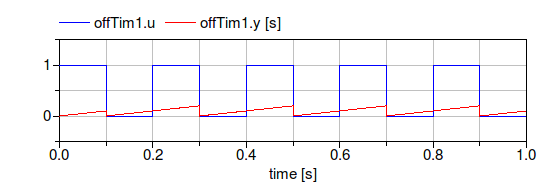

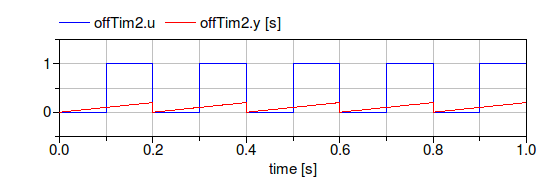

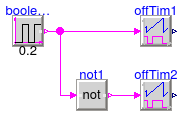

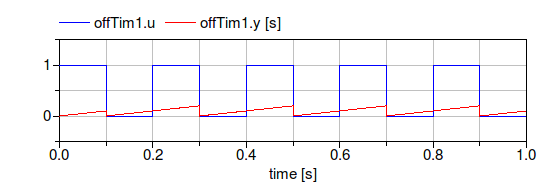

Example model for off timer

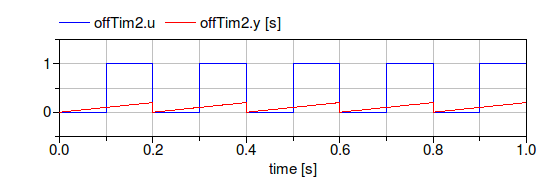

Information

Example that demonstrates the use of the model

Annex60.Controls.Continuous.OffTimer.

The input to the two timers are alternating boolean values.

Whenever the input becomes false(=0), the timer is reset.

The figures below show the input and output of the blocks.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

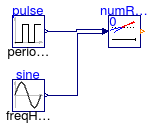

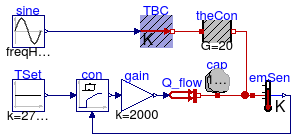

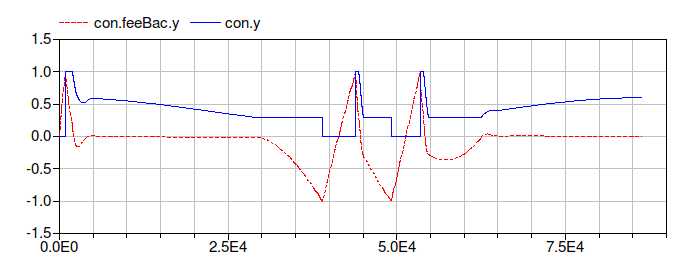

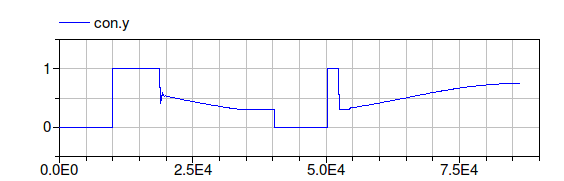

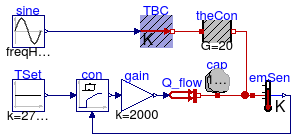

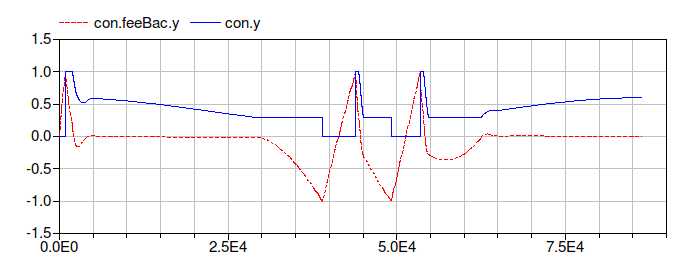

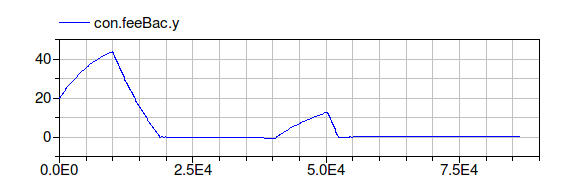

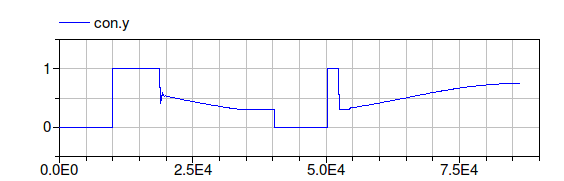

Example model for PID controller with hysteresis

Information

Example that demonstrates the use of the PID controller

with hysteresis. The control objective is to keep

the temperature of the energy storage cap

at 40°C.

The controller con is parameterized to

switch on if the control error is bigger than

eon=1.

The output of the controller remains above ymin=0.3 until the control

error is smaller than eoff=-1, at which

time the controller outputs y=0 until the

control error is again bigger than 1.

The figure below shows the control error

con.feeBac.y and the control signal

con.y.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model PIDHysteresis

extends Modelica.Icons.Example;

Annex60.Controls.Continuous.PIDHysteresis con(

pre_y_start=false,

controllerType=Modelica.Blocks.Types.SimpleController.PI,

yMin=0.3,

Ti=600,

Td=60);

Modelica.Blocks.Sources.Constant TSet(k=273.15 + 40, y(unit="K")) ;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap(C=1000000, T(start=

313.15, fixed=true));

Modelica.Thermal.HeatTransfer.Sources.PrescribedTemperature TBC;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon(G=20);

Modelica.Blocks.Math.Gain gain(k=2000);

Modelica.Thermal.HeatTransfer.Sensors.TemperatureSensor temSen;

Modelica.Thermal.HeatTransfer.Sources.PrescribedHeatFlow Q_flow;

Modelica.Blocks.Sources.Sine sine(

freqHz=1/86400,

offset=273.15,

amplitude=20,

phase=-1.5707963267949,

y(unit="K"));

equation

connect(TSet.y, con.u_s);

connect(TBC.port, theCon.port_a);

connect(theCon.port_b, cap.port);

connect(con.y, gain.u);

connect(cap.port, temSen.port);

connect(temSen.T, con.u_m);

connect(gain.y, Q_flow.Q_flow);

connect(Q_flow.port, cap.port);

connect(sine.y, TBC.T);

end PIDHysteresis;

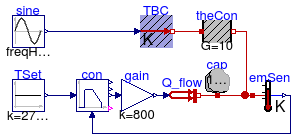

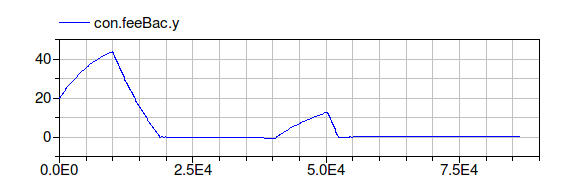

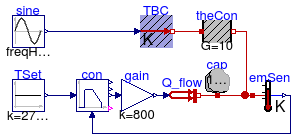

Example model for PID controller with hysteresis and timer

Information

Example that demonstrates the use of the PID controller

with hysteresis and off timer.

The example is identical to

Annex60.Controls.Continuous.Examples.PIDHysteresis,

except that the controller also has an off timer.

This timer keeps the control signal at y=0

for a period of minOffTime=1000 seconds.

This may be used to avoid short-cycling if the load is small

and the system has little heat capacity.

The figure below shows the control error

con.feeBac.y and the control signal

con.y.

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

model PIDHysteresisTimer

extends Modelica.Icons.Example;

Annex60.Controls.Continuous.PIDHysteresisTimer con(

yMin=0.3,

minOffTime=10000,

controllerType=Modelica.Blocks.Types.SimpleController.PI,

Ti=60,

Td=10);

Modelica.Blocks.Sources.Constant TSet(k=273.15 + 40, y(unit="K")) ;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap(C=100000, T(start=

293.15, fixed=true));

Modelica.Thermal.HeatTransfer.Sources.PrescribedTemperature TBC;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon(G=10);

Modelica.Blocks.Math.Gain gain(k=800);

Modelica.Thermal.HeatTransfer.Sensors.TemperatureSensor temSen;

Modelica.Thermal.HeatTransfer.Sources.PrescribedHeatFlow Q_flow;

Modelica.Blocks.Sources.Sine sine(

freqHz=1/86400,

offset=273.15,

amplitude=20,

phase=-1.5707963267949);

equation

connect(TSet.y, con.u_s);

connect(TBC.port, theCon.port_a);

connect(theCon.port_b, cap.port);

connect(con.y, gain.u);

connect(cap.port, temSen.port);

connect(temSen.T, con.u_m);

connect(gain.y, Q_flow.Q_flow);

connect(Q_flow.port, cap.port);

connect(sine.y, TBC.T);

end PIDHysteresisTimer;

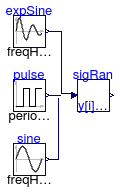

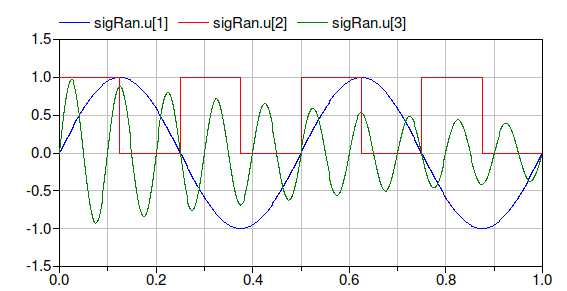

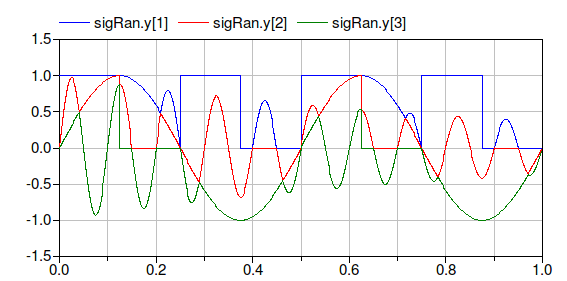

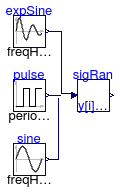

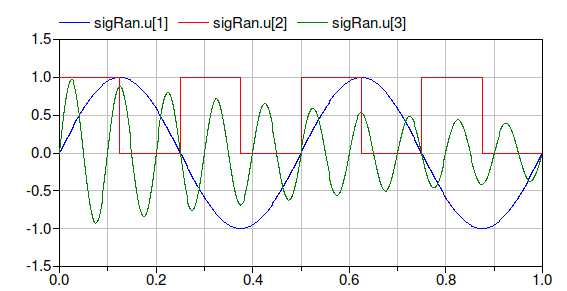

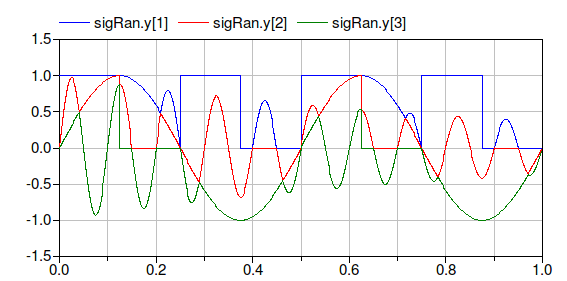

Example model for signal ranker

Information

Example that demonstrates the use of the signal ranker model.

The figure below shows the input and output signals of the block.

Note that

sigRan.y[1] ≥ sigRan.y[2] ≥ sigRan.y[3].

Extends from Modelica.Icons.Example (Icon for runnable examples).

Modelica definition

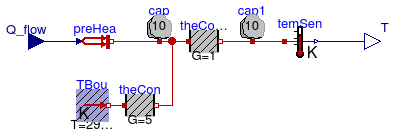

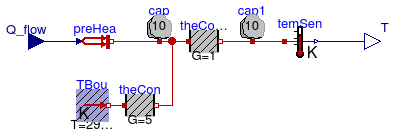

Plant model

Information

Plant model for

Annex60.Controls.Continuous.Examples.LimPIDWithReset.

consisting of a simple heat transfer model.

Implementation

To compare the effect of the controller output reset, the plant and control

models have been implemented in separate blocks so they can be instantiated

twice in the system model with the appropriate control settings.

Extends from Modelica.Blocks.Icons.Block (Basic graphical layout of input/output block).

Connectors

| Type | Name | Description |

|---|

| input RealInput | Q_flow | Heat flow rate added to system [W] |

| output RealOutput | T | Controlled temperature [K] |

Modelica definition

model Plant

extends Modelica.Blocks.Icons.Block;

Modelica.Blocks.Interfaces.RealInput Q_flow(unit="W")

;

Modelica.Blocks.Interfaces.RealOutput T(unit="K")

;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap(

C=10,

T(fixed=true,

start=293.15)) ;

Modelica.Thermal.HeatTransfer.Components.HeatCapacitor cap1(

C=10,

T(fixed=true,

start=293.15)) ;

Modelica.Thermal.HeatTransfer.Sensors.TemperatureSensor temSen

;

Modelica.Thermal.HeatTransfer.Sources.PrescribedHeatFlow preHea

;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon(G=5)

;

Modelica.Thermal.HeatTransfer.Sources.FixedTemperature TBou(T=293.15)

;

Modelica.Thermal.HeatTransfer.Components.ThermalConductor theCon1(G=1)

;

equation

connect(Q_flow, preHea.Q_flow);

connect(T, temSen.T);

connect(TBou.port, theCon.port_a);

connect(cap.port, theCon1.port_a);

connect(theCon1.port_b, cap1.port);

connect(cap1.port, temSen.port);

connect(theCon.port_b, cap.port);

connect(preHea.port, cap.port);

end Plant;

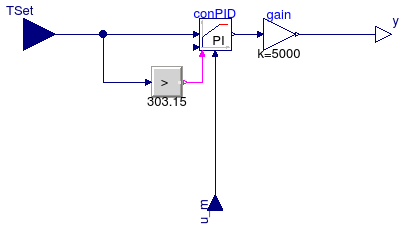

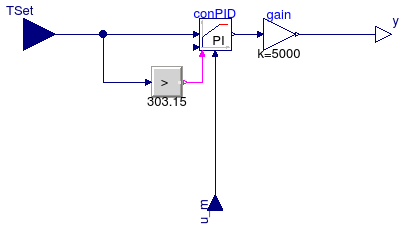

PID controller with optional output reset

Information

Controller model for

Annex60.Controls.Continuous.Examples.LimPIDWithReset.

The controller is reset whenever the input signal becomes bigger than

30°C.

Implementation

To compare the effect of the controller output reset, the plant and control

models have been implemented in separate blocks so they can be instantiated

twice in the system model with the appropriate control settings.

Extends from Modelica.Blocks.Icons.Block (Basic graphical layout of input/output block).

Parameters

| Type | Name | Default | Description |

|---|

| Reset | reset | Annex60.Types.Reset.Disabled | Type of controller output reset |

Connectors

| Type | Name | Description |

|---|

| input RealInput | TSet | Temperature set point [K] |

| input RealInput | u_m | Measured temperature [K] |

| output RealOutput | y | Control signal |

Modelica definition

model Controller

extends Modelica.Blocks.Icons.Block;

parameter Annex60.Types.Reset reset=Annex60.Types.Reset.Disabled

;

Modelica.Blocks.Interfaces.RealInput TSet(unit="K") ;

Modelica.Blocks.Interfaces.RealInput u_m(unit="K")

;

Modelica.Blocks.Interfaces.RealOutput y

;

Annex60.Controls.Continuous.LimPID conPID(

final reset=reset,

yMax=1,

yMin=0,

controllerType=Modelica.Blocks.Types.SimpleController.PI,

Ti=1,

k=10) ;

Modelica.Blocks.Math.Gain gain(k=5000)

;

Modelica.Blocks.Logical.GreaterThreshold trigger(threshold=303.15)

;

equation

connect(conPID.y,gain. u);

connect(trigger.y,conPID. trigger);

connect(u_m, conPID.u_m);

connect(conPID.u_s, TSet);

connect(trigger.u, TSet);

connect(gain.y, y);

end Controller;

http://iea-annex60.org

Annex60.Controls.Continuous.Examples.LimPID

Annex60.Controls.Continuous.Examples.LimPID

Annex60.Controls.Continuous.Examples.LimPIDWithReset

Annex60.Controls.Continuous.Examples.LimPIDWithReset

Annex60.Controls.Continuous.Examples.NumberOfRequests

Annex60.Controls.Continuous.Examples.NumberOfRequests

Annex60.Controls.Continuous.Examples.OffTimer

Annex60.Controls.Continuous.Examples.OffTimer

Annex60.Controls.Continuous.Examples.PIDHysteresis

Annex60.Controls.Continuous.Examples.PIDHysteresis

Annex60.Controls.Continuous.Examples.PIDHysteresisTimer

Annex60.Controls.Continuous.Examples.PIDHysteresisTimer

Annex60.Controls.Continuous.Examples.SignalRanker

Annex60.Controls.Continuous.Examples.SignalRanker

Annex60.Controls.Continuous.Examples.LimPIDWithReset.Plant

Annex60.Controls.Continuous.Examples.LimPIDWithReset.Plant

Annex60.Controls.Continuous.Examples.LimPIDWithReset.Controller

Annex60.Controls.Continuous.Examples.LimPIDWithReset.Controller